Design World – November 2022

Motion System Applications

Vibration Isolators Aid

Detection and Measurement of Gravitational Waves

Detecting and measuring gravitational waves requires extremely sensitive instrumentation. In the 1970s, American physicist Rainer Weiss pioneered the concept of using lasers for interferometric gravitational wave detection. Extensive research over the past several decades has produced extremely advanced interferometric techniques, providing a means to observe phenomena in the universe that previously could not be studied otherwise.

"With laser interferometry we can retrieve information from spaces in the universe that are otherwise not accessible, and we can look back in time much further,” said Dr. Harald Lück, Research Group Leader for the Laser Interferometry and Gravitational Wave Astronomy division of the Max Planck Institute in Gravitational Physics (alternately known as the Albert Einstein Institute) in Hannover, Germany.

Together with its UK colleagues, and Leibniz Universität Hannover, the Laser Interferometry and Gravitational Wave Astronomy division of the Albert Einstein Institute operates the gravitational-wave detector, GEO600. Funded by the Max Planck Society, and the Science and Technology Facilities Council, GEO600 is a ground-based interferometric gravitational wave detector located near Hannover, Germany. The GEO600 project aims at the direct detection of gravitational waves by means of a laser interferometer.

Scientists at GEO600 have pushed research into interferometry related technologies to their limits, encompassing laser stabilization, absorption-free optics, control engineering, vibration damping, and data acquisition and processing.

“GEO600 is also the first gravitational wave detector that uses squeezed laser light to improve sensitivity,” continued Dr. Lück. “Squeezed states are of high interest since they show a squeezed uncertainty which can be used to improve the sensitivity of measurement devices beyond the usual quantum noise limits. The quantum nature of light has an influence at all frequencies, but at about 1,000 to 4,000 Hz – where signals from supernovae and the birth of neutron stars are expected – quantum noise dominates at these higher frequencies. Hence, it is at high frequencies where we currently benefit from squeezing the most.”

“Individual photons will hit the detector at an uneven rate,” explained Lück. “Because of quantum fluctuations, these photons will show up as a fluctuating background signal that could completely obscure the expected short gravitational wave signal from the event itself. GEO scientists have managed to tame unwanted signal noise by manipulating the fluctuations, so as to produce this squeezed

light. Both LIGO and Virgo now use squeezed light. Virgo uses a squeezed light source built and operated by GEO, while LIGO uses a squeezed light of its own design.”

The increased sensitivity of the LIGO detectors is based on many technologies developed and tested at GEO600.

Shielding optics from terrestrial vibrations

A significant challenge in gravitational wave interferometry is to get rid of disturbances like air pressure and temperature fluctuations, as well as seismic vibrations of all sorts that would conceal a signal.

“The central elements in all gravitational wave detectors are mirrors,” said Dr. Lück. “The GEO600 mirrors, which are used to direct the laser beams, weigh about 6 kg. These mirrors are suspended as triple pendulums, so that they’re isolated from various disturbances. Thin threads made of quartz glass – fused silica fibers – are bonded directly onto the mirrors and a second pendulum mass, which means there is no friction at the point of contact. This increases the overall sensitivity of GEO600 through reduced mechanical loss.”

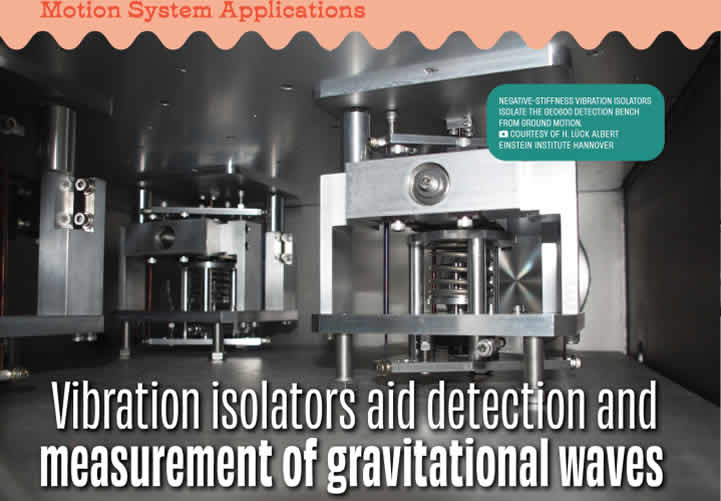

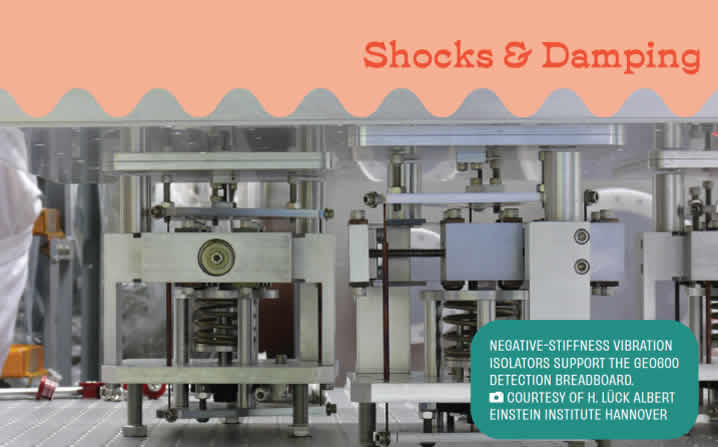

The detection bench, carrying mode matching optics, a Faraday isolator, an output mode cleaner, and the photo diode are situated on a breadboard, which is sitting upon three Negative-Stiffness vibration isolators to isolate from ground motion. This entire assembly is enclosed within a vacuum chamber

Specific attention was given to the selection of vibration isolators supporting the breadboard within the vacuum chamber. Seismic disturbances are particularly noticeable when making measurements in the low-frequency range below 100 Hz.“We selected Negative-Stiffness vibration isolators because they are very simple to use, compact, and operate without the need for compressed air or electronic cabling,” explained Dr. Lück. “In a vacuum we try to minimize connecting cable components.

"These isolators are not only more vacuum compatible, they are more reliable than air tables or active systems. They isolate very well from the outside world.”

Negative-Stiffness vibration isolation

Negative-Stiffness vibration isolation was developed by Minus K Technology. These vibration isolators are compact, and do not require electricity or compressed air which enables sensitive instruments to be located wherever a production facility or laboratory needs to be located. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

One big advantage of Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz vertically and horizontally (with some versions at 1.5 Hz horizontally). Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.

“Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism,” said Dr. David Platus, inventor of Negative-Stiffness isolators, and President and Founder of Minus K Technology. “The net vertical stiffness is made low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of low vertical and horizontal natural frequencies and high internal structural frequencies.”

Negative-Stiffness isolators deliver high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93% isolation efficiency at 2 Hz; 99% at 5 Hz; and 99.7% at 10 Hz.

“One issue with our systems that we use is the suppression of the resonance,” added Dr. Lück. “And here, the Negative-Stiffness isolators turn what is usually considered a disadvantage into an advantage. If you build a low-frequency suspension system then you typically find that the mechanical Q values go down and the dissipation goes up. I think that is what the Minus K isolators use for keeping the resonance peak low enough, and that is a neat use of turning this seeming disadvantage into an advantage.”

Minus K Technology Inc. www.minusk.com

Contact: Minus K Technology, Inc., 460 Hindry Avenue, Unit C, Inglewood, CA 90301, 310-348-9656 E-mail: request@minusk.com Web: www.minusk.com

|