Machine Design February 1993

Vibration

Isolation

Smoothing Out Bad Vibes

New vibration isolators

perform ten times better than air springs

DAVID L. PIATUS

Minus K Technology Inc.,

Los Angeles, Calif.

Negative-stiffness-mechanism isolators

offer unsurpassed vibration control

In the 2 to 100-Hz

range.

Vibration is a fact of life in most industrial settings, but

in some applications it cannot be tolerated. When fabricating

microelectronics, machining to extreme tolerances, or using

industrial laser/optical systems, for example, a vibration-free

environment is a must.

Until recently, air springs offered the best vibration isolation.

But newly developed negative-stiffness mechanism (NSM) isolators

control 2 to 100-Hz vibrations 10 to 100 times better than air

springs.

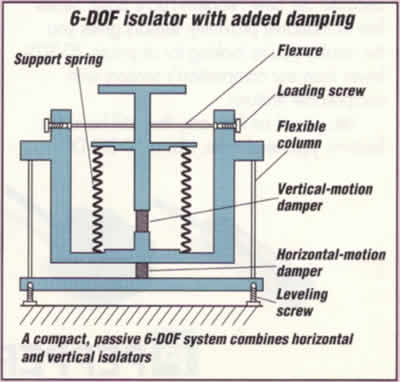

Vertical and horizontal isolators combined in a single package

provide a passive, mechanical 6-DGF (degrees of freedom) isolator.

They are suitable for fixed static loads, applications where

load changes are small, and those where adjustments for load

changes can be made. Among the benefits the devices bring to

a manufacturing environment are:

- Better resolution and accuracy from inspection instruments.

- Higher yield from fabrication equipment because of fewer rejects or rework.

- Greater versatility in locating vibration sensitive equipment, such as on upper floors of a building instead of the basement.

- Require no air or power supply.

- Have no valves to maintain or replace.

- Do not generate heat.

- Cannot contaminate clean rooms with dirty air.

- Offer natural-frequency adjustment independent of load.

- Are all metal; they can be used in hard vacuums, at high temperatures, and in radiation environments.

- Used its passive elements in active systems, give faster

response to load changes and can automatically adjust natural-frequency.

- Negative-stiffness isolators use mechanical components to keep vibrations from sensitive equipment.

The net result is a compact isolator capable of low vertical

and horizontal stiffnesses and high internal structural frequencies.

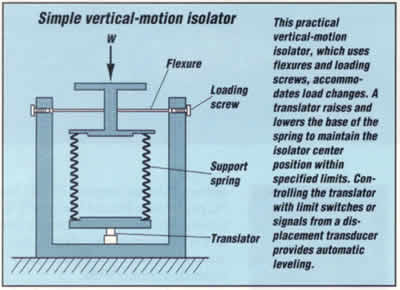

Vertical-motion isolation

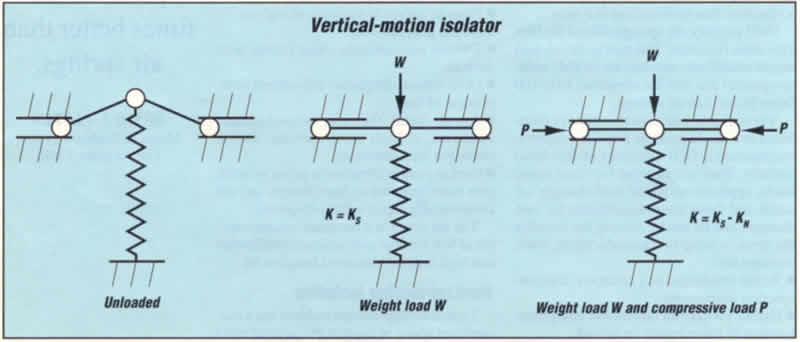

Typical vertical-motion isolators use a conventional spring

to support the pay load and a negative-stiffness mechanism ("snap-through"

or "over-center" mechanism) to cancel some or all

of the spring stiffness. This produces low to zero net vertical

stiffness. The approach has been used successfully to simulate

zero gravity when testing large space structures, for example,

but has not been previously used in 6-DOF isolation systems.

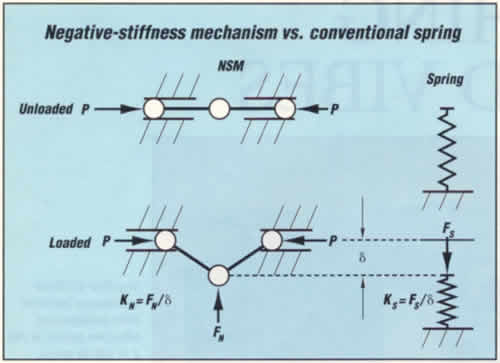

One form of NSM consists

of two bars hinged at the center, supported at their outer

ends on pivots which are free to move horizontally, and

loaded in compression by opposing forces P, When

unloaded, the bars are aligned and in unstable equilibrium

{the center position of the NSM.) When displaced downward

an amount

One form of NSM consists

of two bars hinged at the center, supported at their outer

ends on pivots which are free to move horizontally, and

loaded in compression by opposing forces P, When

unloaded, the bars are aligned and in unstable equilibrium

{the center position of the NSM.) When displaced downward

an amount ![]() ,

force FN which opposes the

motion holds the center hinge in equilibrium. For small

values of

,

force FN which opposes the

motion holds the center hinge in equilibrium. For small

values of ![]() ,

the ratio between FN and

,

the ratio between FN and ![]() is linear and expressed as the negative stiffness, KN.

The behavior of a conventional spring is also shown, both

unloaded and deflected an amount

is linear and expressed as the negative stiffness, KN.

The behavior of a conventional spring is also shown, both

unloaded and deflected an amount ![]() by the force FS. Here, FS acts in the direction of the displacement

by the force FS. Here, FS acts in the direction of the displacement ![]() to hold the deflected spring in equilibrium. The ratio

of FN to

to hold the deflected spring in equilibrium. The ratio

of FN to ![]() is the positive stiffness KS.

is the positive stiffness KS.

Combining the spring and NSM produces a vertical-motion

isolator. When a load W deflects the spring to

the center position of the isolator, the spring provides

vertical stiffness. Applying forces P to the bars

creates the NSM, which cancels some or all of the spring

stiffness. The resulting isolator stiffness is K= KS-KN,

and can be made to approach zero while the spring still

supports the weight. Flexures used in place of hinged

bars offer advantages in some systems. Loading screws,

piezoelectric devices, and various other means produce

compressive loads.

Horizontal-motion isolation

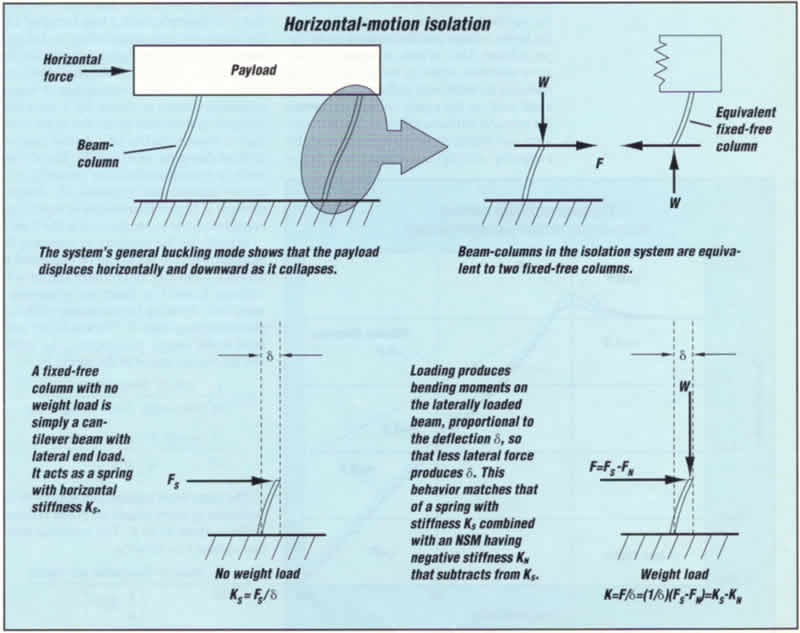

A set of flexible columns or beam-columns that behave as springs,

combined with NSMs, isolate horizontal motion. This is illustrated

by a payload supported on two flexible columns. A horizontal

force displaces the payload without significant rotation because

the columns are much stiffer vertically than horizontally. Horizontal

stiffness can approach zero by loading the columns near their

critical buckling loads, thereby producing very low natural

frequencies for horizontal vibrations.

The system's general buckling mode is illustrated by a deformed

shape. As the system collapses the payload moves horizontally

and downward. Adding stops to limit horizontal displacement

produces a system that is fail-safe against collapse due to

inadvertent overload. Limiting horizontal displacements to small

values changes the buckling mode and increases the buckling

strength nominally by a factor of four Of course, the system

does not isolate when the payload hits the stops.

This approach uses the beam-column effect: axial loading reduces

bending stiffness of a beam-column. The beam-columns in the

isolation system shown are equivalent to two fixed-free columns.

For a single fixed-free column with no load weight, the beam-column

is simply a cantilever beam with lateral (horizontal) end load,

and acts as a spring with horizontal stiffness KS.

Load W produces bending moments on the laterally loaded

beam, proportional to the deflection ![]() ,

so that less lateral force produces

,

so that less lateral force produces ![]() .

This behavior matches that of a spring with stiffness KS combined with an NSM having negative stiffness KN that subtracts from KS. As W approaches the critical buckling load. KN approaches KS and the net horizontal

stiffness of the beam-column approaches zero.

.

This behavior matches that of a spring with stiffness KS combined with an NSM having negative stiffness KN that subtracts from KS. As W approaches the critical buckling load. KN approaches KS and the net horizontal

stiffness of the beam-column approaches zero.

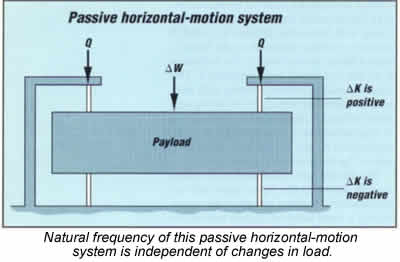

The simple horizontal-motion isolation system shown in the figure

passively accommodates changing weights while maintaining a

fixed isolation-system natural frequency. Two sets of flexible

columns preloaded with axial load Q support the payload.

Each set has an upper and lower column. The lower column supports

part of the weight plus the axial preload; the upper column

supports only the axial preload.

Because of the columns' axial flexibility and other flexibility

in the system, increasing payload weight increases axial load

on the lower column and decreases it on the upper column. This,

in turn, increases the negative-stiffness effect in the lower

column, reducing its horizontal stiffness. Decreasing axial

load on the upper column decreases the negative stillness effect

in the upper column, increasing its horizontal stiffness. By

properly sizing the upper and lower columns, the horizontal

stiffness changes in proportion to changes in payload weight,

so the natural frequency remains unchanged.

Changing the preload Q changes the negative-stiffness

effect in the upper and lower columns in the same direction,

thereby providing an independent means for adjusting the system

horizontal stiffness and resonant frequency.

Damping

Damping limits resonant responses. Reducing stiffness with the

NSM magnifies the inherent system damping, resulting in high

hysteretic damping. High hysteretic damping is more desirable

than high viscous damping because it limits resonant responses

without significantly reducing isolation efficiencies at higher

frequencies.

Transmissibility curves shown for a hysteretically damped system

illustrate this fact. For example, with a loss factor of 1.0,

the resonant transmissibility is 1.4 and transmissibilities

at higher frequencies deviate only slightly from the ideal undamped

curve. For comparison, a transmissibility curve is shown for

a viscously damped system that gives the same resonant transmissibility

of 1.4 (the viscous critical-damping ratio is 0.5). The difference

in transmissibilities between viscously damped and hysteretically

damped systems at higher frequencies is significant considering

the log scale used in the figure.

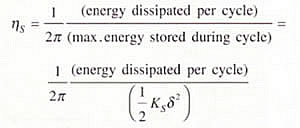

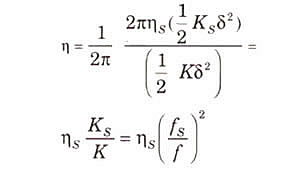

Magnifying the damping by reducing the

stiffness with the NSM can be explained as follows. Consider an ordinary spring with stiffness KS and loss factor

Magnifying the damping by reducing the

stiffness with the NSM can be explained as follows. Consider an ordinary spring with stiffness KS and loss factor ![]() S,

supporting a mass and vibrating harmonically with displacement

amplitude

S,

supporting a mass and vibrating harmonically with displacement

amplitude ![]() .

The loss factor is related to the energy dissipated

in the spring and the energy stored in the spring by

.

The loss factor is related to the energy dissipated

in the spring and the energy stored in the spring by

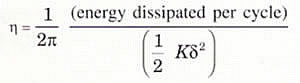

The same basic relationship applies to

the isolation system where an NSM reduces stillness

from KS to K. The

resulting isolation system loss factor is as the NSM reduces net stiffness K, the maximum

elastic energy stored during the cycle, and associated

with

as the NSM reduces net stiffness K, the maximum

elastic energy stored during the cycle, and associated

with ![]() ,

decreases, but the energy dissipated per cycle does

not, The energy dissipated per cycle is the energy dissipated

by the spring, and can be expressed by the first equation.

Combining the two equations gives

,

decreases, but the energy dissipated per cycle does

not, The energy dissipated per cycle is the energy dissipated

by the spring, and can be expressed by the first equation.

Combining the two equations gives where

where ![]() S is system natural frequency based on the spring stiffness

and

S is system natural frequency based on the spring stiffness

and ![]() is

system natural frequency based on the reduced stiffness.

is

system natural frequency based on the reduced stiffness.

The system's general buckling mode is illustrated by a deformed

shape. As the system collapses the payload moves horizontally

and downward. Adding stops to limit horizontal displacement

produces a system that is fail-safe against collapse due to

inadvertent overload. Limiting horizontal displacements to small

values changes the buckling mode and increases the buckling

strength nominally by a factor of four Of course, the system

does not isolate when the payload hits the stops.

This approach uses the beam-column effect: axial loading reduces

bending stiffness of a beam-column. The beam-columns in the

isolation system shown are equivalent to two fixed-free columns.

For a single fixed-free column with no load weight, the beam-column

is simply a cantilever beam with lateral (horizontal) end load,

and acts as a spring with horizontal stiffness KS.

Load W produces bending moments on the laterally loaded

beam, proportional to the deflection ![]() ,

so that less lateral force produces

,

so that less lateral force produces ![]() .

This behavior matches that of a spring with stiffness KS combined with an NSM having negative stiffness KN that subtracts from KS. As W approaches the critical buckling load. KN approaches KS and the net horizontal

stiffness of the beam-column approaches zero

.

This behavior matches that of a spring with stiffness KS combined with an NSM having negative stiffness KN that subtracts from KS. As W approaches the critical buckling load. KN approaches KS and the net horizontal

stiffness of the beam-column approaches zero

Damping can be greatly magnified in a typical NSM isolation

system. For example, consider a vertical-motion isolation system,

where the spring's frequency is 5 Hz, and the NSM's is 0.5 Hz.

According to the third equation, the isolation system loss factor

equals the spring loss factor multiplied by 100. Therefore,

1% structural damping in the spring produces 100% structural

damping in the isolation system.

Adding damping improves the suspension system, particularly

high-damping viscoelastic materials. Consider a suspension consisting

of a steel spring and viscoelastic damper. The system stiffness

is the sum of the spring and damper stiffnesses, but essentially

all the damping comes from the viscoelastic material. By adding

negative stiffness with an NSM equal to the stiffness of the

steel spring, the resulting suspension behaves dynamically as

though the payload were suspended on only the damper. This approach

produces very low natural frequencies and high damping in compact

systems.

The damping behavior of viscoelastic materials typically falls

between the viscous and the hysteretic curves shown in the transmissibility

graph. Loss factors for some materials exceed 1.0 over certain

ranges of temperature and frequency, and manufacturers can tailor

materials to particular ranges of interest. For example, some

materials have loss factors exceeding 1.0 at room temperature

and the low frequencies of interest for vibration isolation

-0.2 lo 1.5 Hz. Thus, system resonant transmissibilities lower

than 1.4, and transmissibilities at the higher frequencies close

to ideal undamped systems, are possible.

System stiffness can be reduced below that of the damping material

alone, producing system resonant transmissibilities significantly

lower than 1.4. However under these conditions in totally passive

systems, creep instability can occur. By retaining some positive

stiffness from the mechanical suspension, the system is inherently

stable.

The simple horizontal-motion isolation system shown in the figure

passively accommodates changing weights while maintaining a

fixed isolation-system natural frequency. Two sets of flexible

columns preloaded with axial load Q support the payload.

Each set has an upper and lower column. The lower column supports

part of the weight plus the axial preload; the upper column

supports only the axial preload.

Because of the columns' axial flexibility and other flexibility

in the system, increasing payload weight increases axial load

on the lower column and decreases it on the upper column. This,

in turn, increases the negative-stiffness effect in the lower

column, reducing its horizontal stiffness. Decreasing axial

load on the upper column decreases the negative stillness effect

in the upper column, increasing its horizontal stiffness. By

properly sizing the upper and lower columns, the horizontal

stiffness changes in proportion to changes in payload weight,

so the natural frequency remains unchanged.

Changing the preload Q changes the negative-stiffness

effect in the upper and lower columns in the same direction,

thereby providing an independent means for adjusting the system

horizontal stiffness and resonant frequency.

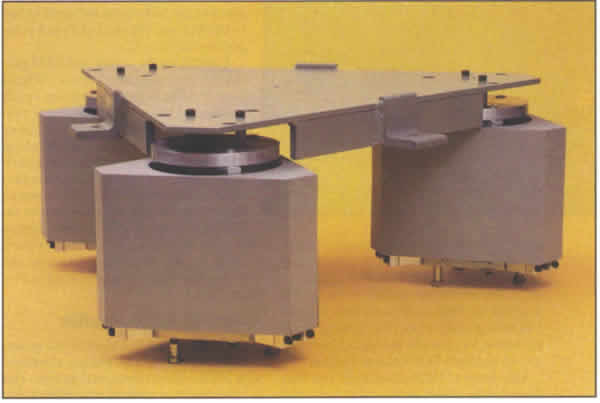

SYSTEM CONFIGURATIONS

SYSTEM CONFIGURATIONS

Isolators for handling vertical and horizontal

vibrations can be combined to produce various

configurations of 6-DOF isolators.

Passive systems

Compact, passive 6-OOF isolators with added damping

are available with height and width approximately

equal. Size envelopes for this configuration are

comparable to pneumatic isolators that support

the same loads. Other isolators depart radically

from conventional shapes, including low-profile

configurations for use where space is limited.

NSM suspensions arc applicable for a wide range

of loads. For example, a small isolated platform

that supports a microscope and a large system

that support an entire fabrication-room floor

can both give very low frequencies.

Active and automatic leveling systems

An important feature of NSM systems is their capability

for stiffness and frequency control by adjusting

the NSMs. For example, vertical and horizontal-motion

isolators can be combined with a servosystem.

Controlling the vertical-motion translator produces

an automatic leveling system in which the horizontal-motion

natural frequency is insensitive to changes in

payload weight. Likewise, controlling the vertical-motion

NSM makes vertical-motion natural frequency insensitive

to weight changes. As another example, consider

step-and-repeat systems, such as photolithography

machines, with stages that accelerate and decelerate.

Feed-forward control can adjust the NSMs to stiffen

the system during stage acceleration and deceleration

and soften the system during exposures or measurements.

Real-world systems

NSM isolation system behavior closely approaches the transmissibility

curves up to frequencies where the isolator structure itself

resonates. Because the isolators are simple, compact, elastic

structures, their internal-structural resonances arc readily

predictable and can be kept at high frequencies. Isolator resonances

are above 100 Hz in practical 6-DOF systems with isolation system

natural frequencies (frequencies at which the system of payload

and suspension resonates) of 0.2 Hz or lower.

System natural frequencies in the range of 0.5 to 1.5 Hz are

of interest for a wide range of applications, particularly with

low system resonant response, near-hysteretic damping behavior

and isolator internal-structural resonances above 100 Hz. With

high-damping viscoelastic materials, resonant transmissibilities

as low as 1.4 are practical with passive NSM-isolation systems.

Automatic centering systems using an actuator controlled by

signals from displacement or velocity sensors further enhance

performance. Also, because NSM isolators are simple elastic

structures and viscoelastic materials that deform, their isolation

performance does not degrade with micromotions typical of laboratory

floors and fabrication rooms, as with conventional pneumatic

isolators.

GAUGING PERFORMANCE

GAUGING PERFORMANCE

NSM-isolator performance between a system's

natural frequency and first internal structural

frequency closely approaches that of a perfect single-DOF

system. Commercially available models have internal

structural frequencies above 100 Hz.

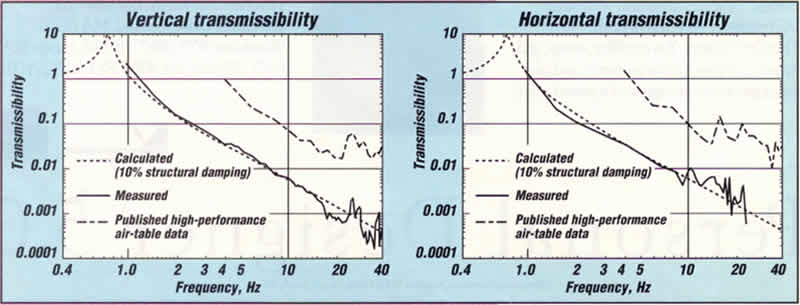

Measured transmissibility versus frequency curves

for a payload supported on three NSM isolators are

shown in the figures. Calculated curves for single-DOF

systems are shown for comparison, as are transmissibility

curves for a high-performance air table, based on

manufacturer's published data.

The measured curves are truncated at the upper frequencies

by signal-to-noise ratios and at the lower frequencies

by transducer frequency-responses.