Minus K Educational Giveaway – October 2023

Vibration Isolation Supports the Search for Memory in Soft, Amorphous Solids

The Soft Mechanics Laboratory at California Polytechnic State University (Cal Poly is researching soft, amorphous solids like foams, concentrated emulsions and bulk metallic glasses to determine whether these materials remember deformations that were applied repeatedly in the past, and how this information could be encoded in their microscopic structure and behaviors.

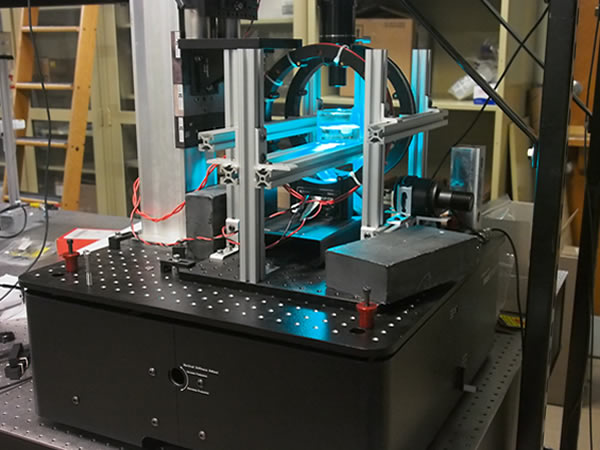

Cal Poly’s 2D solid experiment: A self-made interfacial shear rheometer of the two circular coils that create magnetic forces to deform the sample material in a glass dish and measured by the microscope suspended above, all sitting on a Minus K 100BM-1 negative-stiffness vibration isolator.

Nathan Keim, Assistant Professor of Physics at Cal Poly’s Soft Mechanics Laboratory in San Luis Obispo, has for well over a decade been conducting research on memory, self-organization and other non-equilibrium behaviors of soft materials under deformation.

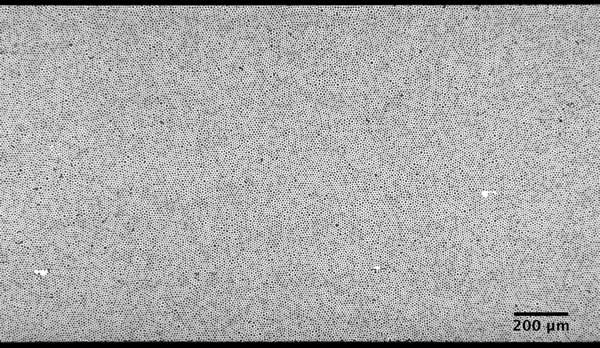

This includes experimental studies of the mechanisms of plasticity in disordered solids, and liquid interfaces. With his students, the lab conducts experiments on interfacial materials, made up of microscopic particles adsorbed at an oil-water interface, using these two-dimensional systems as models of soft, amorphous solids like foams, concentrated emulsions and bulk metallic glasses.

“Amorphous solids like foam, sand, and ice cream feature many particles crowded together. Each particle is fully constrained by its neighbors, but the material is disordered so these constraints vary greatly,” said Professor Keim. “When the material is put under sufficient stress, we know that local groups of particles rearrange by squeezing past one another, but the way these microscopic processes organize and give rise to macroscopic behaviors of the material is still not well understood.”

“We focus on deformations that are large enough to cause these rearrangements and change the material, but too small to disrupt the material completely and cause it to start flowing.” explained Professor Keim. “This creates the possibility that the material can retain a detailed memory of how it was deformed in the past. Exploring how these memories are stored and how they can be retrieved is an opportunity to learn more about the mechanisms at play when these materials deform.”

Interfacial Shear Rheometer and Managing Vibrations

To facilitate this research, Professor Keim and his team have constructed an instrument, a kind of interfacial shear rheometer, which allows a two-dimensional amorphous solid to be deformed while measuring its mechanical properties.

The apparatus uses a pair of magnetic coils to move a magnetized needle embedded in the material, deforming the material with pN (piconewton) forces. By simultaneously recording the motion of tens of thousands of particles in the material, they can connect what is happening on the microscopic and macroscopic scales – a rare and highly desirable ability in the study of materials.

“Since our research basically takes place on the surface of a dish of water, the experiment is especially sensitive to low-frequency vibrations that excite surface waves and agitate the material under study,” added Professor Keim. “The building where the physics department, and the Soft Mechanics Lab is housed, has severe vibrations at 5 Hz due to the many fume hoods in the building, as well as the HVAC system.”

When these vibrations are too strong, they do not just introduce noise, but actually trigger rearrangements of the particles within the sample material – essentially altering the sample during the measurement. Even when they do trigger rearrangements, low-frequency disturbances also add noise to the mechanical measurements and limit the ability to deform the material precisely and repeatedly.

For vibration isolation, the experiments were being conducted on a tabletop platform resting on passive balloon isolators. But this was not sufficient to dampen vibrations satisfactorily. So the lab began performing experiments at night when the chemistry fume hoods were not in operation, which helped mitigate the problem, but still required considerable computer processing afterwards to stabilize imaging.

“These vibration limitations had grown more important as we began to examine our material’s response when the exact same deformation is applied hundreds of times, in order to study the possibility of learning and memory effects,” continued Professor Keim.

Having looked at both optical air tables and active vibration cancellation systems as potential solutions for the vibration problem, and determined that neither was satisfactory for cancelling vibrations at very low frequencies, the lab selected Negative-Stiffness vibration isolation.

2D solid material sample: A layer of polystyrene particles at the interface between oil and water. The black bars at the top and bottom are the boundaries that are moved to shear the material.

Negative-Stiffness vibration isolation was developed by Minus K Technology, an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. The company’s isolators are used by more than 300 universities.

These vibration isolators are compact, and do not require electricity or compressed air which enables sensitive instruments to be located wherever a production facility, laboratory or observatory needs to be set up, whether that be in a basement, or on a building’s vibration-compromised upper floors, or rooftop. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz* vertically and horizontally (with some versions at 1.5 Hz horizontally). (*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

“Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism,” said Erik Runge, Vice President of Minus K Technology. “The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies.”

Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz.

Vibration Isolation Results

“The Negative-Stiffness isolators are performing very well at 5 – 10 hertz, where we were having difficulty with vibrations,” said Professor Keim. “We are no longer forced to conduct our experiments at night, nor do we have excessive computer post-processing of our images.”

“Undergraduate students are doing much of the experiments,” added Professor Keim. “To have an isolator that is simple, straightforward and easy to understand is a big benefit for my students.”

“And importantly, with the difficulties we were experiencing with vibrations and lack of evident solutions, I felt our experiments were pushing the limits with managing vibrations,” continued Professor Keim. “That is no longer the case.”

Soft Mechanics Lab, Physics Department, College of Science & Mathematics, California Polytechnic State University (Cal Poly)

The Cal Poly Soft Mechanics Lab, part of the Cal Poly College of Science and Mathematics, is focused on memory, self-organization, and other non-equilibrium behaviors of soft materials under deformation and driving. This includes experimental studies of the mechanisms of plasticity in disordered solids, of pinned liquid interfaces, and of suspensions of swimming organisms.

|