Mono and Stereo - September 2021

Negative-Stiffness Vibration Isolation Enables Precision Helix One And Helix Two Turntable Performance

The DÖHMANN AUDIO Helix One and Helix Two turntables integrate the advanced technology of Negative-Stiffness vibration isolation to provide the ultimate in noise suppression, and deliver the micro-signals buried in the vinyl grooves of LPs

By Jim McMahon

Mark Döhmann of DÖHMANN AUDIO

Vinyl remains unsurpassed for reproducing music,” said Mark Döhmann, Founder of Döhmann Audio. “To convey vinyl’s rich, nuanced potential a turntable must have precise speed control and operate without producing mechanical or electronic noise. The goal is an uncompromised signal emerging from a silent background, resulting from precisely designed construction that eliminates noise and gives precision speed control for ideal playback.”

This goal has been very closely approximated with the release of the Helix One and Helix Two turntables, representing a breakthrough in analog playback design and execution. These turntables are a showcase for micro-signal architecture, a new way of thinking borne from the world of ultra-precision sub-atomic research, where the removal of unwanted vibration is critical to achieving precision results.

Helix Two turntable

The Helix One and Helix Two turntables reward the listener with the closest facsimile to master tape yet realized. Their specifications demand the ultimate in noise suppression and vibration isolation systems, allowing the turntables and pick-up arms to deliver the micro-signals buried in the vinyl grooves of LPs.

“Every aspect of the turntables' design requires the preservation of the micro-signals found in the grooves of the LP to be retrieved with as little modification and distortion as physically and electronically possible,” added Döhmann. “The turntables incorporate a number of engineering advances to deliver the lowest resonance profile for any pickup arm and LP combination.”

Close-up of a stylus and LP grooves

These engineering advances include: a) mechanical crossover technology; b) a tri-modal platter system; c) an edge-damping ring; d) a tone arm damping system; e) resonance-tuned suspension; f) a diamond-like coating, amorphous material-bearing friction modifier; g) high-torque, adjustable-drive speed selections; and h) a velocity adjustment lock.

But what contributes to making the Helix One and Helix Two turntables truly unique is their highly precise, fully-integrated vibration isolation system.

The Need For Vibration Isolation

Vibration isolation in the playback process of high-end audio systems is crucial. Any external vibration, no matter how slight, even someone walking near the turntable or vibration from floor-mounted speakers, is sensed by the turntable’s stylus and affects the sound being played back from the record. Capacitors, resistors, transistors, tube amplifiers and other electronic components are likewise sensitive to vibration.

“Analog audio is a very detailed and information rich storage and retrieval mechanism,” continued Döhmann. “The enemy of retrieval information is vibration, which can modulate with the needle as it works its way through the groove. If you can remove exterior vibration and allow the needle to operate in an optimally quiet method or platform, then you will get more information out because your noise is much lower.”

Most manufacturers of high-end turntables recognize that external vibration is a problem, and will go to great lengths to minimize it in their turntable designs. Quality turntables, for example, are built with superb platter bearings to minimize rumble. They often incorporate high-mass platters that are designed to increase speed stability and reduce flutter. They might use exotic materials to dampen vibrations without deadening the sound. Tone arms have their own set of vibration and resonance characteristics which manufacturers attempt to isolate from the audible frequencies through geometry, localized vibration isolation and damping.

Aftermarket air-based vibration isolators supporting the entire turntable have become a popular accessory. These systems typically have a power pump to supply air, with a tank that holds the pressurized air and delivers steady pressure to the isolator. The somewhat noisy pump is usually located outside of the room where the audio equipment is located, and the air hoses are run over to the tank and vibration isolating platform. Air systems are usually a less than optimal set-up, however, as they do achieve some isolation vertically, but provide limited horizontal isolation. They do not isolate to the extent that is really needed at very low resonance frequencies.

Negative-Stiffness Supports Precision Turntable Performance

Mark Döhmann selected Negative-Stiffness vibration isolation as a fully-integrated component to support his Helix One and Helix Two turntables. Negative-Stiffness is rapidly gaining popularity for use with extremely sensitive audio reproduction systems. It was originally developed to eliminate vibrations in ultra-sensitive research with atomic force microscopy and nanotechnology. Today, it is widely used in hundreds of university research facilities worldwide, where ultra-precision vibration stabilization is required.

Negative-Stiffness vibration isolation was developed and patented by Dr. David Platus, Founder of Minus K Technology (www.minusk.com). Dr. Platus is one of the most respected designers in the field of vibration isolation, and holds numerous patents in the field. A close association between Dr. Platus and Mark Döhmann led to the design of a custom low-frequency isolation platform for the Helix One and Two turntables. This technology is a world-first for audio turntable design.

“The turntable sits directly on top of the Negative-Stiffness isolator,’ said Döhmann. “This is a full integration. At this level the isolator becomes the turntable.”

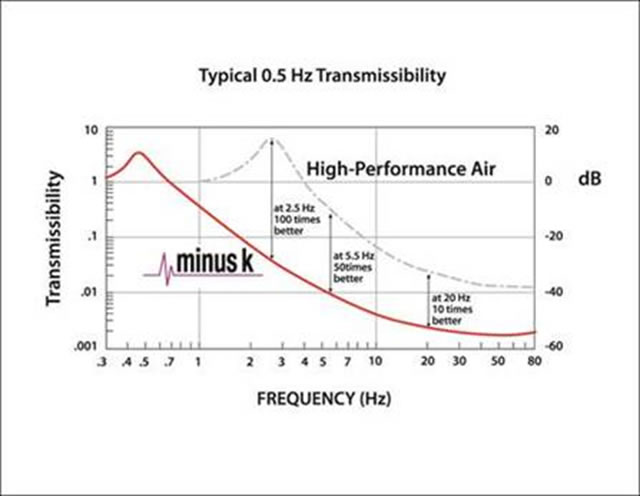

Negative-Stiffness isolators provide a unique capability to the field of audio fidelity, employing a completely mechanical concept in low-frequency vibration isolation, with no air or electricity required. Whether with turntables, tube electronics, CD transports or other audio equipment, Negative-Stiffness isolators have the flexibility of custom tailoring resonant frequencies vertically to 0.5 Hz* and horizontally to 1.5 Hz (with some products as low as 0.5 Hz horizontally).

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

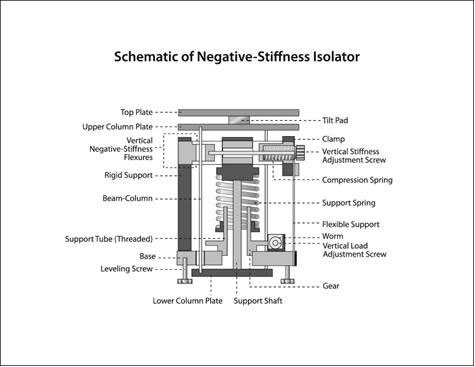

Schematic of a Minus K Negative-Stiffness Isolator

Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a negative-stiffness mechanism. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. Not just vertically – which is very important for audio systems to isolate against footfall – but also horizontally. The horizontal vector is often overlooked because horizontal structural vibrations are less obvious, but nevertheless, transmitted to the turntable and other audio equipment.

Performance

If a turntable is set up on anything other than a concrete slab floor or other large inert mass, then every time someone walks in the vicinity of the turntable, the vibrations from their footsteps are transmitted through the floor to the support stand and into the turntable, and finally show up in the recording. People will literally tiptoe around their audio playback systems, but the playback process is so sensitive that it will still pick up footsteps in the hallways or rooms some distance away. The Negative-Stiffness isolator is extremely effective at cancelling out these vibrations, referred to as footfall.

Transmissibility, Minus K Negative-Stiffness isolator versus air table.

Negative-Stiffness isolators enable a sense of harmonic rightness. Instruments sound much more like real instruments, and voices sound like they are in a real acoustic space, with real air around them. The ability to “see” clearly into the entire three-dimensional soundstage is greatly enhanced. Improvements in rhythm and pace are captivating.

“Very noticeable is the bass region,” continued Döhmann. “When the bass is too prominent it can sound muddy. This is often caused by a reinjection of vibration into the mechanism adding to the amplitude of the needle movement. This creates more signal that what is physically in the groove. But the Negative-Stiffness isolator cleans that up, so that the bass is more natural, more like the real thing.”

“The Helix One and Helix Two turntables set new benchmarks for performance in Analog,” added Döhmann. “Coupled with a Schroder CB arm and Negative-Stiffness vibration isolation, these tables offer unsurpassed sonic results. An immediate distinction in terms of sound accuracy is noticed by experienced listeners. This is not a direct-drive sound, rather it presents as an organic rightness with macro- and micro-dynamics that astonish.”

ABOUT DÖHMANN AUDIO

For more information, contact Döhmann Audio, Unit 4, 1-7 Friars Road, Moorabbin Vic 3189, Australia; email enquiry@dohmannaudio.com; www.dohmannaudio.com.

ABOUT MINUS K TECHNOLOGY, INC.

Minus K® Technology, Inc. was founded in 1993 to develop, manufacture and market state-of-the-art vibration isolation products based on the company’s patented negative-stiffness technology. Minus K products are used in a broad spectrum of applications including microscopy, nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft, and high-end audio. The company is an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. Minus K customers include private companies and more than 300 leading universities and government laboratories in 52 countries.

Dr. David L. Platus is the inventor of negative-stiffness isolators, and President and Founder of Minus K Technology, Inc. (www.minusk.com). He earned a B.S. and a Ph.D. in Engineering from UCLA, and a diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to founding Minus K Technology he worked in the nuclear, aerospace and defense industries conducting and directing analysis and design projects in structural-mechanical systems. He became an independent consultant in 1988. Dr. Platus holds over 20 patents related to shock and vibration isolation.

For more information on Negative-Stiffness isolators please contact Steve Varma, Minus K Technology, Inc.; 460 Hindry Ave., Unit C, Inglewood, CA 90301; Phone 310-348-9656; Fax 310-348-9638; email request@minusk.com; www.minusk.com.

|