Motion System Design - April 2009

Shake, rattle, roll no more

Negative-stiffness

vibration isolation improves imaging from laser and optical

systems.

Jim McMahon

Dave Kushin

Minus K Technology, Inc. Inglewood, Calif.

Laser and optical systems, whether used in academic labs or

industry, very susceptible to vibrations from the environment

so these instruments frequently need vibration isolation.

They measure a very few angstroms or nanometers of displacement

and need an absolutely stable surface upon which to rest.

Any vibration, coupled into the mechanical structure of the

instrument, causes vertical noise and a fundamental inability

to measure these kinds of high-resolution features.

As industry continues to broaden

laser and optical research and applications, necessitating

more sensitive equipment and expanded lab facilities,

vibration-handicapped environments will become more prevalent,

and better vibration isolation than what has been available

will be required.

As industry continues to broaden

laser and optical research and applications, necessitating

more sensitive equipment and expanded lab facilities,

vibration-handicapped environments will become more prevalent,

and better vibration isolation than what has been available

will be required.

Negative-stiffness-mechanism or NSM vibration isolation enables

laser and optic instruments such as scanning probe microscopes

or SPMs, micro-hardness testers, and optical profilers to

operate under severe vibration that would otherwise be impractical

with passive and electronic isolation systems. Traditionally,

large air tables are the isolators used for laser and optical

equipment. The ubiquitous passive-system tables, adequate

up until a few years ago, are now being seriously challenged

by the need for more refined imaging requirements. Benchtop

air systems do provide limited isolation vertically and very

little isolation horizontally. However, SPMs, for example,

have unforgiving vibration isolation requirements that are

unparalleled in the laser and optical world.

The vertical axis is the most sensitive for most SPMs. These

systems can also be quite sensitive to vibrations in horizontal

axes. For the lowest possible noise floor, on the order of

an Angstrom, vibration isolation must be used. NSM isolators

have the flexibility of custom tailoring resonant frequencies

vertically and horizontally, providing increased isolation

performance over air tables.

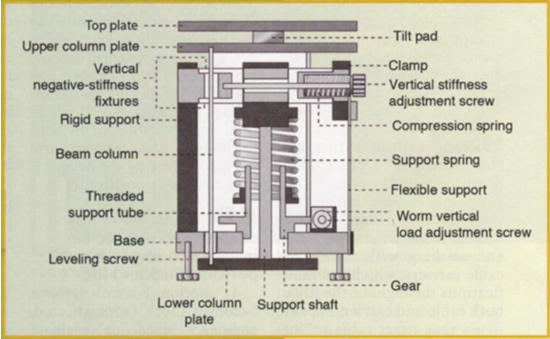

NSM vibration isolator schematic

A vertical stiffness adjustment screw

can regulate compression force on negative-stiffness

flexures. The screw raises or lowers the base of the

support spring in response to varying weight loads to

keep flexures in their straight, unbent operating position.

Flexures are used in the isolators to avoid stiction

and friction.

Similarly, laser-based interferometers also are sensitive devices that must resolve nanometer-sized motion and features. They often have very long mechanical paths that make them even more sensitive to vibrations. The sophisticated modern ellipsometry techniques that allow this high performance rely on low noise to detect fringe movement. Properly isolating an interferometer allows it to provide the highest possible resolution.

Interferometers and other optical systems

such as optical profilers are often quite complex, and

have long optical paths that can lead to angular magnification

of vibrations. Air tables can make the problems worse

because they have a resonant frequency that often matches

that of floor vibrations - typically 2 to 3 Hz. In addition,

their isolation efficiency is quite limited below about

8 Hz. NSM isolators provide isolation in these environments

when air tables cannot.

Interferometers and other optical systems

such as optical profilers are often quite complex, and

have long optical paths that can lead to angular magnification

of vibrations. Air tables can make the problems worse

because they have a resonant frequency that often matches

that of floor vibrations - typically 2 to 3 Hz. In addition,

their isolation efficiency is quite limited below about

8 Hz. NSM isolators provide isolation in these environments

when air tables cannot.

Negative-stiffness-mechanism vibration isolation systems

have proliferated for laser and optical applications.

Not only is it a workable vibration solution, but it

costs significantly less - to one-third the price of

active and traditional passive systems - making it an

economical component for cost-conscious designers. This

isolation is used internationally, in applications including

nanotechnology, biological sciences, semiconductors,

materials research, zero-g simulation of spacecraft,

and audio for private companies, universities, and government

laboratories.

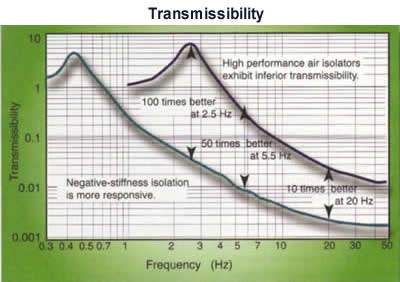

Negative-stiffness isolators provide transmissibility, vibrations

through the isolator relative to input vibrations. Transmissibility

with negative-stiffness is substantially improved over air

systems, and even over active isolation systems.

Also known as electronic force cancellation, active isolation

uses electronics to sense motion, and then adds forces electronically

to effectively cancel out or prevent it. The efficiency of

active isolation systems is adequate for applications with

the latest lasers and optics as they can start isolating as

low as 0.7 Hz. However, because they ran on electricity, they

can be negatively influenced by problems of electronic dysfunction

and power modulation, which can interrupt scanning. Active

systems also have limited dynamic range that is easy to exceed,

causing the isolator to go into positive feedback and generate

noise underneath the equipment. Although active systems have

fundamentally no resonance, their transmissibility does not

roll off as fast as NSM isolators.

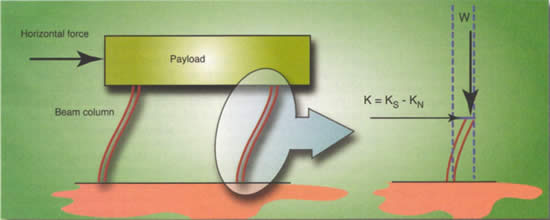

NSM horizontal motion isolator

A horizontal-motion isolation system

is represented by two beam-column isolators. Horizontal

stiffness can be made to approach zero by loading the

beam columns to advance toward critical buckling load.

Negative-stiffness isolators employ a completely mechanical

mechanism for low-frequency vibration isolation. Vertical-motion

isolation is provided by a stiff spring that supports a weight

load, combined with an NSM. The net vertical stiffness is

lowered without affecting the static load-supporting capability

of the spring. Beam columns connected in series with the vertical-motion

isolator provide horizontal-motion isolation. The horizontal

stiffness of the beam-columns is reduced by the "beam-column"

effect. (A beam-column behaves as a spring combined with an

NSM.) The result is a compact passive isolator capable of

very low vertical and horizontal natural frequencies and high

internal structural frequencies. The isolators (adjusted to

1/2 Hz) achieve 93% isolation efficiency at 2 Hz; 99% at 5

Hz; and 99.7% at 10 Hz.

Horizontal and vertical motion isolators

Negative-stiffness mechanism isolators typically use three

isolators stacked in series: a tilt-motion on top of a horizontal-motion

on top of a vertical-motion isolator.

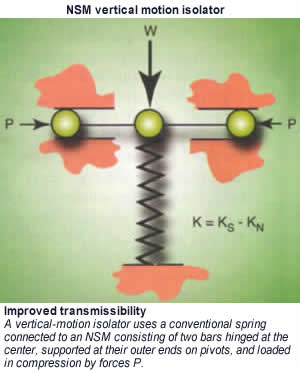

A vertical-motion isolator uses a conventional spring connected

to an NSM consisting of two bars hinged at the center, supported

at their outer ends on pivots, and loaded in compression by

forces P. The spring is compressed by weight W to the operating

position of the isolator. Isolator stiffness is K-Ks- Kn where:

Ks = Spring stiffness

Kn = Magnitude of a negative stiffness, a function of the

length of the bars and the load P. The isolator stiffness

can be made to approach zero while the spring supports the

weight W.

Transmissibility of the of a passive

negative stiffness vibration isolator - the vibration

that transmits through the isolator as a function of input

vibrations - can be 10 to l00 times better than high-performance

air tables depending on the vibration frequency

Transmissibility of the of a passive

negative stiffness vibration isolator - the vibration

that transmits through the isolator as a function of input

vibrations - can be 10 to l00 times better than high-performance

air tables depending on the vibration frequency

Each isolator behaves like two fixed-free beam-columns loaded

axially by a weight load W. Without the weight load, the beam-columns

have horizontal stiffness Ks. With the weight load, lateral

bending stiffness is reduced by the beam-column effect. This

behavior is equivalent to a horizontal spring combined with

an NSM so that the horizontal stiffness is K = Ks - Kn where

Kn is the magnitude of the beam-column effect. Horizontal

stiffness can be made to approach zero by loading the beam

columns to approach their critical buckling load.

Minus K Technology Inc. develops and manufactures vibration

isolation products based on its patented negative-stiffness-mechanism

technology. For more information, contact Steve Varma at (310)

348-9656 or sales@minmk.com, or visit www.mimisk.com.

Meet the inventor

Dr. David L. Platus is the inventor of negative-stiffness

mechanism vibration isolation systems, founder of Minus K,

and holds over 20 patents related to shock and vibration isolation.

He earned a B.S. and a Ph.D. in Engineering from UCLA, and

a diploma from the Oak Ridge School of (Nuclear) Reactor Technology.

Previously, Platus worked in nuclear, aerospace, and defense

industries conducting and directing analysis and design projects

in structural-mechanical systems. He became an independent

consultant in 1988.