Photonics.com - February 2011

Improving Micro-Raman/AFM Systems Imaging Using Negative-Stiffness Vibration Isolation

Negative-stiffness vibration isolators can easily support the heavy weight of a combined AFM/micro-Raman system, and isolate it from low frequency vibrations more effectively than high-performance air tables or active isolation systems.

By Jim McMahon

The need for precise vibration isolation with scanning probe

microscopy (SPM) and near-field scanning optical microscopy

(NSOM) systems is becoming more critical as resolutions

continue to bridge from micro to nano. Whether used in academic

labs or commercial facilities, SPM and NSOM systems are

extremely susceptible to vibrations from the environment.

When measuring a very few angstroms or nanometers of displacement,

an absolutely stable surface must be established for the

instrument. Any vibration coupled into the mechanical structure

of the instrument will cause vertical and/or horizontal

noise and bring about a reduction in the ability to measure

high resolution features – the vertical axis being

the most sensitive for SPMs, but they can also be quite

sensitive to vibrations in the horizontal axis.

Traditionally, bungee cords and high-performance air

tables have been the vibration isolators most used for

SPM and NSOM work. The ubiquitous passive-system air

tables, adequate until a decade ago, are now being seriously

challenged by the need for more refined imaging requirements.

Bench top air systems provide limited isolation vertically

and very little isolation horizontally. Also at a disadvantage

are the active isolation systems, known as electronic

force cancellation, that use electronics to sense the

motion and then put in equal amounts of motion electronically

to compensate and cancel out the motion. Active systems

are somewhat adequate for applications with lasers and

optics, as they can start isolating as low as 0.7 Hz,

but because they run on electricity they can be negatively

influenced by problems of electronic dysfunction and

power modulations, which can interrupt scanning.

Traditionally, bungee cords and high-performance air

tables have been the vibration isolators most used for

SPM and NSOM work. The ubiquitous passive-system air

tables, adequate until a decade ago, are now being seriously

challenged by the need for more refined imaging requirements.

Bench top air systems provide limited isolation vertically

and very little isolation horizontally. Also at a disadvantage

are the active isolation systems, known as electronic

force cancellation, that use electronics to sense the

motion and then put in equal amounts of motion electronically

to compensate and cancel out the motion. Active systems

are somewhat adequate for applications with lasers and

optics, as they can start isolating as low as 0.7 Hz,

but because they run on electricity they can be negatively

influenced by problems of electronic dysfunction and

power modulations, which can interrupt scanning.

Lately, the introduction of integrated microscopy systems

employing multiple microscopes is enabling more complex optical

measurements, but these systems are also much heavier, and

there has been little vibration isolation technology available

for such heavy instrumentation. Air tables, which have been

liberally used for optics applications, are not ideal for

these nanoscale resolution systems because of their inability

to effectively isolate vibrations below 20 Hz. Nor can active

systems be used with these newer combination systems because

of their inability to handle heavy instrumentation. But now,

negative-stiffness mechanism (NSM) vibration isolation is

quickly becoming the choice for SPM and NSOM systems. This

includes applications using atomic force microscopy (AFM)

integrated with micro-Raman spectroscopy, where negative-stiffness

vibration isolation is particularly well adapted. In fact,

it is the application of negative-stiffness isolation that

has enabled AFMs to be truly integrated with micro-Raman into

one combined system. Negative-stiffness isolators can handle

the heavy weight of the combined AFM/micro-Raman system, as

well as isolate the equipment from low frequency vibrations,

a critical set of factors that high-performance air tables

and active systems cannot achieve.

AFM with Micro-Raman Integrated

AFM with Micro-Raman Integrated

The integration of AFM with micro-Raman enables a sizable

improvement in data correlation between the two techniques

and expanded Raman measurement and resolution capabilities.

Micro-Raman is a spectroscopic NSOM technique used in

condensed matter physics and chemistry to study vibrational,

rotational, and other low-frequency modes in a system.

It relies on scattering of monochromatic light, usually

from a laser in the visible, near infrared or near ultraviolet

range.

The laser light interacts with phonons or other excitations

in the system, resulting in the energy of the laser photons

being shifted up or down. The shift in energy gives information

about the phonon modes in the system. Scanning samples in

a micro-Raman system, however, suffers from several problems.

As a sample is scanned, even a very flat sample, it is hard

to keep the distance of the lens to the sample constant. Thus,

as one goes from pixel to pixel under the lens of a Raman,

a mixture of sample and air is sampled in the voxel (volumetric

picture element) that is illuminated. This causes intensity

variations in the Raman that are unrelated to the chemical

composition of the sample and are artifactual. This is even

more pronounced with rough samples and standard methods of

autofocus are simply not accurate enough for a whole host

of problems that are being investigated today. Additionally,

the point spread function, which determines the resolution

of the Raman image, is significantly broader where there are

contributions from the out-of-focus light and this reduces

resolution.

The atomic force microscope, being a very high-resolution

type of scanning probe microscope, has demonstrated resolution

of fractions of a nanometer, making it one of the foremost

tools for imaging, measuring and manipulating matter at the

nano-scale. The information is gathered by "feeling"

the surface with a mechanical probe. Piezoelectric elements

that facilitate tiny but accurate and precise movements on

electronic command enable the very precise scanning.

The AFM consists of a micro-scale cantilever with a sharp

tip (probe) at its end that is used to scan the specimen surface.

The cantilever is typically silicon or silicon nitride with

a tip radius of curvature on the order of nanometers. When

the tip is brought into proximity of a sample surface, forces

between the tip and the sample lead to a deflection of the

cantilever. Resultant characteristics, such as mechanical,

electrostatic, magnetic, chemical and other forces are then

measured by the AFM using, typically, a laser spot reflected

from the top surface of the cantilever into an array of photodiodes.

Most systems employing AFM in concert

with Raman perform separately, executing either an AFM

scan or a Raman scan independently. The recently developed

direct integration of Raman spectroscopy with AFM technique,

however, has opened the door to significantly improved

technique and sample analyses.

Most systems employing AFM in concert

with Raman perform separately, executing either an AFM

scan or a Raman scan independently. The recently developed

direct integration of Raman spectroscopy with AFM technique,

however, has opened the door to significantly improved

technique and sample analyses.

Micro-Raman is a microtechnique, but when AFM is added,

it becomes a nanotechnique. It allows the AFM structural

data to be recorded online and improves the resolution

of the Raman information when the nanometric feedback

of the system adjusts, with unprecedented precision,

the position of each pixel of the sample relative to

the lens. Also the small movements of the AFM stage

provide oversampling which is a well-known technique

for resolution improvement.

One integrated AFM-Raman system developed by Nanonics

Imaging Ltd. in association with major Raman manufacturers

such as Renishaw plc, Horiba JY and others provides

simultaneous and, very importantly, on-line data from

both modalities. This advantage addresses critical problems

in Raman including resolution and intensity comparisons

in Raman images while permitting on-line functional

characterization such as thermal conductivity, elasticity

and adhesion, electrical and other properties. It also

provides for new avenues of improved resolution including

AFM functioning without optical obstruction, parallel

recording with Raman in a wide variety of scanned probe

imaging modalities enabling direct and simultaneous

image comparison and analysis, and high-resolution Raman

mapping.

“Until recently, Raman scattering has remained separate

and removed from the proliferation of insights that the scanned

probe microscopies can give,” says Aaron Lewis, President

of Nanonics Imaging, which was the first to see the potential

of such integration. “Without this integration of the

systems, investigating a sample with scanned probe microscopy

required removing the sample from the micro-Raman spectrometer.

This meant that the exact region that was being interrogated

by Raman could not be effectively correlated with the chosen

SPM imaging technique.”

“Another aspect of optical integration is that SPMs can

measure forces, but they cannot measure distribution of light

in micro-lasers, silicon-based wave guides, fluorescently

stained biological materials, etc.,” explains Lewis.

“For example, there are many important advances occurring

in the application of photonics to silicon structures and

plasmonic metals. In the past, these photonic structures were

in the micrometer range, now they are nanometric.”

The Nanonics platform can be used for structural and

photonic characterization, as well as the structural

and chemical characterization that is available with

AFM and Raman integration.

The Nanonics platform can be used for structural and

photonic characterization, as well as the structural

and chemical characterization that is available with

AFM and Raman integration.

For these applications, Nanonics Imaging is the innovator

of AFM and NSOM systems, including dual tip/sample scanning

AFM systems, the industry’s first NSOM-AFM cryogenic

systems, integrated Raman-AFM systems, multiprobe AFM

and SEM-AFM systems. The company also holds patents

to the largest range of unique nano-probes. These probes

form a NanoToolKit for its unique characterization platforms

with a variety of tasks, such as for nanophotonics,

plasmonics, nanochemical imaging and even nanochemical

deposition based on its singular NanoFountainPen technology.

The company is focused on full integration of AFM technology

with optics, chemical imaging and other analytical tools.

The Nanonics MultiView AFM-NSOM microscope, with its

free optical axis on a standard micro-Raman, now makes

it possible to truly integrate the separate worlds of

Raman and AFM/NSOM nanocharacterization, which has led

to a new era in high-resolution Raman spectroscopy.

Facilitating this integration is not only the geometry

of the AFM/NSOM platform but also a new generation of

AFM glass probes that have very unique characteristics

– such as hollow glass probes with cantilevered

nano-pippets for material deposition, probes with glass

surrounding a single nanowire in the middle for ultrasensitive

electrical measurements, or dual wire glass probes for

thermal conductivity and thermocouple measurements.

Glass probes are ideal for Raman integration because of their

transparency to laser light and no Raman background. They

also expand outward allowing unprecedented correlation of

Raman and AFM, also permitting multiple probes to be brought

easily together, which is very difficult with a standard AFM

Negative-Stiffness Vibration Isolation – Enabling

AFM and Micro-Raman to Function as an Integrated Platform

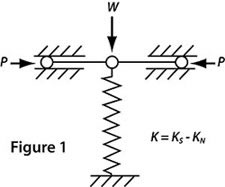

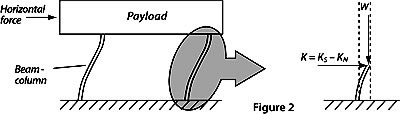

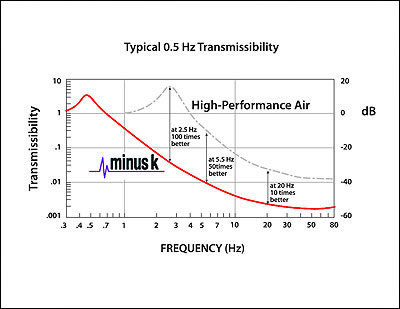

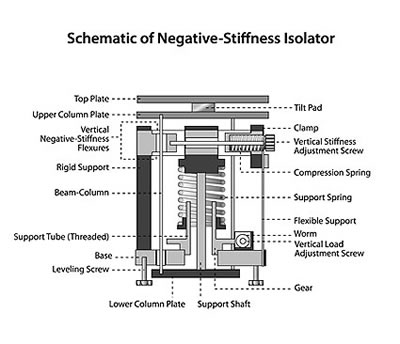

Underlying this pioneering integration AFM with micro-Raman

is negative-stiffness vibration isolation, developed my Minus

K Technology Inc. What negative-stiffness isolators provide

is really quite unique to SPM-Raman and other NSOM systems.

In particular, improved transmissibility of a negative-stiffness

isolator – that is the vibrations that transmit through

the isolator relative to the input floor vibrations. Transmissibility

with negative-stiffness is substantially improved over air

systems and over active isolation systems. Negative-stiffness

isolators employ a unique - and completely mechanical - concept

in low-frequency vibration isolation. Vertical-motion isolation

is provided by a stiff spring that supports a weight load,

combined with a negative-stiffness mechanism. The net vertical

stiffness is made very low without affecting the static load-supporting

capability of the spring. Beam-columns connected in series

with the vertical-motion isolator provide horizontal-motion

isolation. The horizontal stiffness of the beam-columns is

reduced by the "beam-column" effect (A beam-column

behaves as a spring combined with a negative-stiffness mechanism).

The result is a compact passive isolator capable of very low

vertical and horizontal natural frequencies and very high

internal structural frequencies. The isolators (adjusted to

1/2 Hz) achieve 93% isolation efficiency at 2 Hz; 99% at 5

Hz; and 99.7% at 10 Hz.

“Before negative-stiffness vibration isolation was employed, AFM used in conjunction with micro-Raman systems could not maintain adequate imaging integrity while measuring at the nanoscale level,” said Lewis. “Vibration isolation is absolutely necessary for the system’s successful performance, and negative-stiffness isolation has enabled AFM and micro-Raman to function as a truly integrated platform.”

For more information, visit: www.minusk.com or www.nanonics.co.ilAbout the author: Jim McMahon writes about instrumentation technology. His feature stories have appeared in hundreds of industrial and high-tech publications throughout the world and are read by more than 5 million readers monthly. He can be reached at jim.mcmahon@zebracom.net