Photonics Online - July 2011

Negative-Stiffness Vibration Isolation Facilitates Growth Of Large Crystals For Field-Portable Gamma Ray Spectrometers

By Jim McMahon, Zebra Communications

Elimination of external vibrations plays a key role in

maintaining a stable growth process and maximizing the total

volume yield of very large crystals - destined for use in

homeland security field-portable applications for the detection

of gamma rays from special nuclear materials like plutonium

and highly enriched uranium.

At Kansas State University, a unique facility is dedicated

to the research and development of new and innovative

radiation detector technologies. The Semiconductor Materials

and Radiological Technologies (SMART) Laboratory is

the largest university-based radiation detection laboratory

in the country. It focuses on the detection of neutrons

and gamma-rays, primarily those from special nuclear

material (SNM) for homeland security applications. SMART

Lab investigates and fabricates a variety of detectors

which include compact low-power neutron detectors, high-resolution

room-temperature-operated semiconductor gamma ray spectrometers,

pixelated devices for gamma ray or neutron imaging,

and miniaturized gas-filled detectors. The laboratory

builds detectors from start to finish in readily deployable

packages for use in better securing our borders from

nuclear materials such as plutonium and uranium.

The gamma ray detection aspect of the laboratory's research

is focused on the discovery and development of new dense,

high-Z* semiconductor materials, such as cadmium zinc

telluride (CdZnTe or CZT) and mercuric iodide (HgI2),

and several scintillator materials including lanthanum

tribromide (LaBr3) and cerium tribromide (CeBr3). Research

conducted on large crystal growth with high-Z semiconductor

and scintillator materials has produced large crystal

ingot yields. (*The atomic number which uniquely identifies

a chemical element is represented by the symbol Z. Also

known as the proton number, it is the number of protons

found in the nucleus of an atom and identical to the

charge number of the nucleus.)

Gamma rays are electromagnetic radiation of high frequency

(very short wavelength), that are produced by sub-atomic

particle interactions such as electron-positron annihilation,

radioactive decay, fusion and fission. Gamma radiation is

highly penetrating photons, extremely energetic. To directly

detect them is very difficult, however - a material with

a high Z number is needed, representing a high number of

neutrons and protons in the nucleus. Those nuclei tend to

stop gamma rays much better than other elements such as

hydrogen or helium, for example. A crystal with a high-Z

number converts the gamma rays from electromagnetic waves

to excited electrons. The electrons move through the crystal

or create light, one or the other, and produce something

that is possible to be detected. If a crystal is very uniform,

very homogeneous - it can be determined that a gamma ray

interacted in the crystal by the effect that is observed

in it.

Growing Giant Crystal

Growing Giant Crystal

At the SMART Laboratory, crystals of CdZnTe

and the scintillator materials are grown via a vertical

Bridgman furnace. In this process, molten material is

directionally solidified from one end to the other to

produce a large-volume ingot that is a single crystal.

Methods to grow CdZnTe for gamma-ray spectrometers have

been explored since the early 1990s, yet a reliable

system to produce large crystals at an economical cost

has not been achieved until relatively recently.

Higher ingot yields enable smaller, faster and more

accurate sensors, and allow gamma-ray detectors to be

more economical and field-portable - benefits that can

have a significant impact on national security objectives.

Radiation detectors using CZT can operate in direct-conversion

(or photoconductive) mode at room temperature.

Essentially, SMART Lab researchers encapsulate the material

to be grown inside of a quartz ampoule under vacuum.

The quartz tube is put inside the furnace vertically

bringing the material to a molten state between 500°

- 1,100° C. Then they very slowly freeze the material

from bottom to top. If the thermal gradients are correctly

performed, a large crystal will develop. Once the crystal

is grown, it is extracted from the tube, trimmed to

size with a diamond wire saw and polished to produce

a detector.

Vibration Isolation

Critical to maximizing ingot yield is maintaining

a stable crystal growth process through the elimination

of external vibrations.

"The general consensus within the crystal growth

community is that uncontrolled vibrations can destabilize

the growth interface," says Professor Mark Harrison

with SMART Lab. "As the material is freezing from

bottom to top, there is an interface between liquid

and solid, and it sets up a natural convection flow

that is ideal for growing a big, single crystal. If

a vibration disturbs the liquid directly above the forming

crystal solid, it can change the convection patterns

and multiple crystals will form from the previous single

crystal. Which is contrary to our purpose of growing

large, single crystals."

"The general consensus within the crystal growth

community is that uncontrolled vibrations can destabilize

the growth interface," says Professor Mark Harrison

with SMART Lab. "As the material is freezing from

bottom to top, there is an interface between liquid

and solid, and it sets up a natural convection flow

that is ideal for growing a big, single crystal. If

a vibration disturbs the liquid directly above the forming

crystal solid, it can change the convection patterns

and multiple crystals will form from the previous single

crystal. Which is contrary to our purpose of growing

large, single crystals."

"We looked into various active and air table vibration handling systems, and eventually selected Negative-Stiffness vibration isolation," continues Harrison.

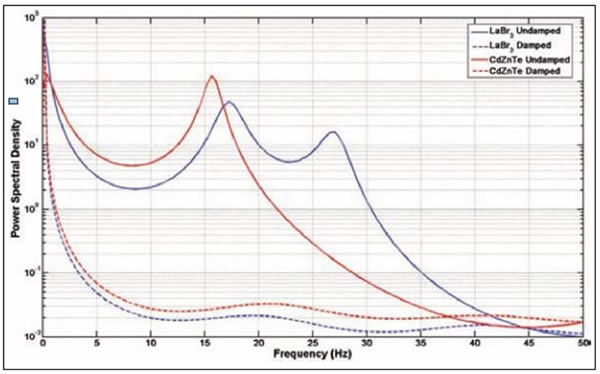

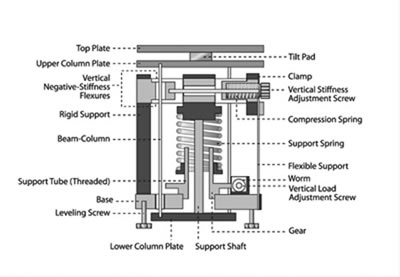

Negative-stiffness mechanism (NSM) isolators have

the flexibility of custom tailoring resonant frequencies

vertically and horizontally. They employ a completely

mechanical concept in low-frequency vibration isolation.

Vertical-motion isolation is provided by a stiff spring

that supports a weight load, combined with a NSM. The

net vertical stiffness is made very low without affecting

the static load-supporting capability of the spring.

Beam-columns connected in series with the vertical-motion

isolator provide horizontal-motion isolation. The horizontal

stiffness of the beam-columns is reduced by the "beam-column"

effect. A beam-column behaves as a spring combined with

a NSM. The result is a compact passive isolator capable

of very low vertical and horizontal natural frequencies

and very high internal structural frequencies.

Negative-stiffness mechanism (NSM) isolators have

the flexibility of custom tailoring resonant frequencies

vertically and horizontally. They employ a completely

mechanical concept in low-frequency vibration isolation.

Vertical-motion isolation is provided by a stiff spring

that supports a weight load, combined with a NSM. The

net vertical stiffness is made very low without affecting

the static load-supporting capability of the spring.

Beam-columns connected in series with the vertical-motion

isolator provide horizontal-motion isolation. The horizontal

stiffness of the beam-columns is reduced by the "beam-column"

effect. A beam-column behaves as a spring combined with

a NSM. The result is a compact passive isolator capable

of very low vertical and horizontal natural frequencies

and very high internal structural frequencies.

Vibration transmissibility with Negative-Stiffness is substantially improved over air systems, which can make vibration isolation problems worse since they have a resonant frequency that can match that of floor vibrations. Transmissibility is a measure of the vibrations that transmit through the isolator relative to the input vibrations. The NSM isolators, when adjusted to 0.5Hz, achieve 93 percent isolation efficiency at 2Hz; 99 percent at 5Hz; and 99.7 percent at 10Hz.

NSM transmissibility is also improved over active systems.

Because they run on electricity, active systems can be negatively

influenced by problems of electronic dysfunction and power

modulations, which can interrupt crystal growth continuity.

Active systems also have a limited dynamic range - which

is easy to exceed - causing the isolator to go into positive

feedback and generate noise underneath the equipment. Although

active isolation systems have fundamentally no resonance,

their transmissibility does not roll off as fast as Negative-Stiffness

isolators.

"One of the concerns we had was surface waves coming

across the ground, which induced vibration in the crystal

growth system," explains Harrison.

"We are located in a basement," Harrison says. "Before we got the NSM system, I could actually see somebody walking down the stairs through the walls with a seismometer. With the Negative-Stiffness system in place, I can't even tell when they are shelling at the nearby Fort Riley military base.

Improving Detection of Special Nuclear Materials

Gamma ray detectors have been around for years, but they

are either very low efficiency, poor performance or they

require liquid nitrogen cooling, such as those employing

germanium. Imagine the difficulty required to take liquid

nitrogen into a remote desert searching for special nuclear

material.

"What we are trying to do at SMART Lab is make it more

feasible, more economical for these detectors to be put

in place at every critical check point, at every airport

and shipping port," Harrison says. "This will

increase the possibility of detecting and intercepting shipments

of special nuclear material, should they occur."

About Kansas State University SMART Laboratory

The SMART Laboratory serves as a center for undergraduate

and graduate student education, as well as a facility, to

accommodate funded research projects from various government

and industrial sponsors. Since the opening of the Laboratory

in 1998, eleven patents have been awarded to SMART Laboratory

researchers for various detector designs, with several more

patents still pending.

The Laboratory's equipment includes an assortment of semiconductor

processing equipment, including a linear-drive diamond cutting

wheel, diamond wire saw, precision slurry saw, wafer dicing

saw, precision lapping and polishing machines, a custom

chemo-mechanical polishing system, a custom 6-pocket e-beam

evaporator, a 4-pocket evaporator, two dual filament evaporators,

an ion mill, vacuum annealing chamber, fission chamber plating

station, mask aligners, microscopes, ovens, grinders, and

an assortment of various furnaces for annealing, sintering,

diffusions and oxidations.

The Lab has numerous crystal growth furnaces used to grow

CdZnTe, LaBr3, and HgI2 crystals for radiation detector

development, which include 40 horizontal and 10 vertical

HgI2 vapor transport furnaces, two high pressure vertical

Bridgman furnaces, two low pressure vertical Bridgman furnaces,

three zone-melt furnaces, a vapor transport purifying furnace,

and a GaAs LPE furnace.

Central to SMART Laboratory is a Class-1000 cleanroom where

radiation detectors are fabricated. The Laboratory is equipped

with a scanning electron microscope, Auger electron analyzing

system, IV and CV tracers, ellipsometer, probers, radiation

sources and Nuclear Instrumentation Module (NIM) electronics

to test and characterize radiation detectors and materials.

About Mark J. Harrison

Mark J. Harrison, PhD, has a B.S. in mechanical engineering,

and an M.S. and PhD in nuclear engineering. Dr. Harrison

holds the position of assistant professor in the Nuclear

and Radiological Engineering Department at the University

of Florida, Gainesville, and participates in radiation detection

research at the Semiconductor Materials and Radiological

Technologies Laboratory (SMART Lab) at Kansas State University,

in collaboration with his colleague, Kansas State University

resident professor Douglas S. McGregor.

Professor Harrison can be reached by contacting the Nuclear

and Radiological Engineering Department, University of Florida;

202 Nuclear Science Bldg., Gainesville, FL 32611; Phone:

352-392-1401 ext. 317; Fax: 352-392-3380; email: mark.harrison@ufl.edu.

The SMART Laboratory is directed by Prof. Douglas McGregor,

who can be reached by contacting the Mechanical and Nuclear

Engineering Department, Kansas State University; 3002 Rathbone

Hall, Manhattan, KS 66506; Phone: 785-532-4093; Fax: 785-532-7057;

email: mcgregor@ksu.edu.

About Minus K Technology, Inc.

Minus K® Technology, Inc. was founded in 1993 to develop,

manufacture and market state-of-the-art vibration isolation

products based on the company's patented negative-stiffness-mechanism

technology. Minus K products are used in a broad spectrum

of applications including nanotechnology, biological sciences,

semiconductors, materials research, zero-g simulation of

spacecraft, and high-end audio. The company is an OEM supplier

to leading manufactures of scanning probe microscopes, micro-hardness

testers and other vibration-sensitive instruments and equipment.

Minus K customers include private companies and more than

200 leading universities and government laboratories in

35 countries.

Dr. David L. Platus is the inventor of negative-stiffness

mechanism vibration isolation systems, and President and

Founder of Minus K Technology, Inc. (www.minusk.com). He

earned a B.S. and a Ph.D. in Engineering from UCLA, and

a diploma from the Oak Ridge School of (Nuclear) Reactor

Technology. Prior to founding Minus K Technology he worked

in the nuclear, aerospace and defense industries conducting

and directing analysis and design projects in structural-mechanical

systems. He became an independent consultant in 1988. Dr.

Platus holds over 20 patents related to shock and vibration

isolation.

For more information on negative-stiffness vibration isolation

please contact Steve Varma, Minus K Technology, Inc.; 460

South Hindry Ave., Unit C, Inglewood, CA 90301; Phone 310-348-9656;

Fax 310-348-9638; email sales@minusk.com; www.minusk.com.