U.S. Tech – November 2021

Vibration Isolation Facilitates Scanning Probe Nanolithography Patterning

By Jim McMahon

Within Saint Louis University’s (SLU) Department of Physics, research has been ongoing in the development of novel techniques for synthesis, characterization and measurement of low dimensional (1D and 2D) systems. This is in hopes to better understand how size, geometry or interfacing various materials and nanostructures influences the properties of the resulting systems.

Nanolithography Research

Nanolithography in general terms is concerned with the study and application of fabricating nanometer-scale structures, meaning patterns with at least one lateral dimension between 1 and 100 nm. A prime focus is very largescale integration (VLSI) and ultralarge-scale integration (ULSI) technology of nanoelectromechanical (NEMS) systems, and the need for better atomic-scale understanding of issues arising from the miniaturization of silicon devices. Under the direction of Dr. Irma Kuljanishvili, who heads up SLU’s nanomaterials and nanofabrication research lab, the group’s focus is on This approach is similar to a technique known as dip pen nanolithography.

In this technique, AFM tips or sharp needles can be employed to transfer small, femtoliter volumes of molecular solutions, or other liquid-based “ink”, to predefined locations on the surface of samples.

“Carbon nanotubes, grapheme and other atomically monolayered materials are being considered as prime candidates for nanoscale science and technology applications, due to their unique and superior combination of electrical, thermal, optical and mechanical properties,” says Kuljanishvili.

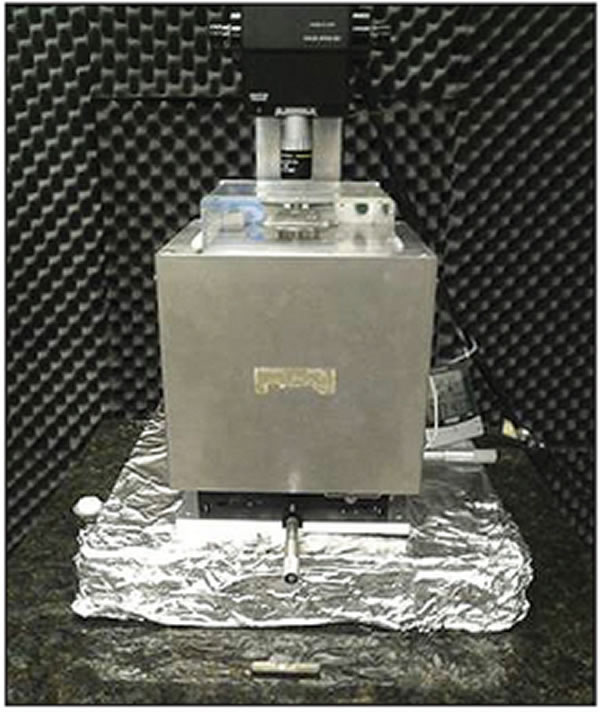

SLU's Negative-Stiffness Vibration Isolation System

Bad Vibrations

Nanopositioning techniques for SPM-based nanolithography applications are sensitive to mechanical vibrations, and even acoustic vibrations, on a similar level to vibration isolation requirements for atomic force microscopy. At Kuljanishvili’s lab, these vibrations were coming up through the floor, and were primarily of low frequency. “We were using almost nothing for vibration isolation,” explains Kuljanishvili. “Position and mechanical stability during patterning is essential for this work. Although acoustic vibrations were relatively easy to take care of, by installing wall padding and frequency

mechanical vibrations are generally much harder to fight.”

Vibration Isolation

To achieve a higher level of vibration isolation, the SLU Department of Physics employed negative-stiffness vibration isolation. Developed by Minus K Technology, negative-stiffness isolators employ a unique and completely mechanical concept in low-frequency vibration isolation.

They do not require electricity or compressed air. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

“Since the installation of Negative-Stiffness vibration isolation, we have been able to perform high-resolution patterning at micro and nanoscales, by significantly eliminating mechanical vibrations,” concludes Dr. Kuljanishvili.

Contact: Minus K Technology, Inc., 460 Hindry Avenue, Unit C, Inglewood, CA 90301, 310-348-9656

E-mail: request@minusk.com Web: www.minusk.com

|