Metrology News - March 2020

Certifying Bowling Ball Surface Roughness

The United States Bowling Congress focuses on research, testing, standardization and certification of bowling equipment used for leagues and tournaments.

The United States Bowling Congress (USBC) is the national governing body of bowling, as recognized by the United States Olympic Committee. It is a membership organization that provides standardized rules, regulations and benefits for certified bowling leagues and tournaments. The USBC is one of the world’s largest sports and recreation membership organizations, in the United States serving approximately 1.4 million bowlers that participate in USBC-certified leagues and tournaments on both the national and local levels.

Critical to the initiatives of the USBC is its Department of Equipment Specifications and Certification, which encompasses testing and research of bowling equipment to set standards and enhance the sport’s credibility.

“There are two sides to bowling – the recreational, and the more competitive,” said Tom Frenzel, Research Engineer with the USBC. “Our focus is on research, testing, standardization and certification of bowling equipment used for leagues and tournaments.”

“Basically, any piece of equipment that touches the bowling lane comes though this department to be evaluated, and determined whether or not it should be allowed to be used,” added Frenzel. “This includes bowling pins, bowling balls, lane panels, lane conditioners, gutters, and kick-back walls in the pin deck.”

To this end, the department uses a number of research and testing methodologies to ensure that not only do these products meet established specifications, but that they are manufactured to within a 4 Sigma quality manufacturing limit, which means within a 0.6 percent defect rate. Essentially, ensuring that 99.4 percent of all bowling products used for certified leagues and tournaments are within designated specifications.

Surface Roughness of Bowling Balls

One area of ongoing research and testing at USBC concerns surface roughness of bowling balls.

Since the early 1990s, better bowling ball coverstocks have been developed. These coverstocks find more friction on the lane, and inevitably hook more. They also disrupt the oil pattern on the lane more, which tends to reduce friction. So the USBC engineering team is trying to better understand the implications of these factors, and better control their outcomes.

“It has become popular to sand bowling balls with different grits of sand paper,” explained Frenzel. “This practice has helped us see how the sanding level on a ball affects its surface layer, then we compare this back to how it performs on the lane.”

“The rougher you get the ball, the more the ball will hook, and the more friction it will find,” continued Frenzel. “The friction will define how the ball accelerates. So more friction means more acceleration, which just means it is changing its speed quicker, or in less time. It is really hooking sooner versus later, or taking less time to hook.”

The standard for measuring surface roughness of bowling balls has been use of a profilometer. Essentially, an instrument used to measure a surface’s profile, in order to quantify its roughness. Critical dimensions as step, curvature and flatness are computed from the surface topography.

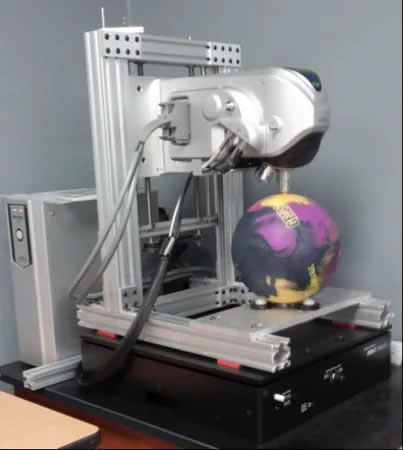

In 2017, the USBC invested into a high-powered 3D laser-scanning, digital confocal microscope, manufactured by Keyence, to take a closer look at the surface roughness of bowling balls. Where the profilometer measures surface topography in a 2-dimensional linear mode, the confocal microscope scans an area in 3D. This has enabled the engineering team to get a much more detailed look at the surface layer topography of bowling ball coverstocks.

In 2017, the USBC invested into a high-powered 3D laser-scanning, digital confocal microscope, manufactured by Keyence, to take a closer look at the surface roughness of bowling balls. Where the profilometer measures surface topography in a 2-dimensional linear mode, the confocal microscope scans an area in 3D. This has enabled the engineering team to get a much more detailed look at the surface layer topography of bowling ball coverstocks.

“We have conducted considerable research on ball coverstocks with the microscope,” said Frenzel. “It easily permits multiple area scans of the ball, and offers many options for additional variables to be assessed."

Need for Vibration Isolation

“When we first started working with the microscope, however, we encountered vibration problems that were inhibiting the instrument’s performance,” added Frenzel. “We began looking for a solution, and selected the Negative-Stiffness vibration isolator, manufactured by Minus K Technology.”

Negative-Stiffness vibration isolation was developed by Minus K Technology, an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. The company’s isolators are used by more than 300 universities.

These vibration isolators are compact, and do not require electricity or compressed air which enables sensitive instruments to be located wherever a production facility, laboratory or observatory needs to be set up, whether that be in a basement, or on a building’s vibration-compromised upper floors, or rooftop. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. These isolators have the flexibility of custom tailoring resonant frequencies to 0.5 Hz* vertically and horizontally (with some versions at 1.5 Hz horizontally).

Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a Negative-Stiffness mechanism. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies.

Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve. Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz.

“As soon as we set up the Negative-Stiffness isolator, the vibration problem immediately disappeared,” added Frenzel. “It is hard to describe how well it has worked for us. Before vibration isolation the microscope was unusable, and it worked perfectly after the Negative-Stiffness isolator was put into place.”