|

|

Newsletter November 2020 | Menu of Newsletters

You might have thought, maybe for only a

few moments, that your audio system was sounding especially good. With that

feeling, you would have rated the sound a top score of "10". Then those magical

moments ended and your system returned to it's normal - but still good -

performance level. Well, folks, the Minus K

CT-2 Isolation

Platform could raise your system score to an "11" and keep it there! Highly

recommended for systems that are already high performance and where you want to

coax the maximum performance from your audio investment....

Dr. David L.

Platus is President and Founder and is the principal inventor of the

technology. He earned a B.S. and a Ph.D. in Engineering from UCLA, and a

diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to

founding Minus K® Technology he worked in the nuclear, aerospace and

defence industries conducting and directing analysis and design projects in

structural-mechanical systems. He became an independent consultant in 1988. Dr.

Platus holds over 20 patents related to shock and vibration

isolation.

Ultra-Thin 2.7" High CT-2 Product

Attributes:

- Isolation performance is typically 10 to 100 times

better than air systems

- No air or electric power is

required

- Nothing to wear out

- No

maintenance

A complete description of the

patented

Negative-stiffness design can be found on the

Technology page of the manufacturers Web site. The Minus K platform is

completely silent and requires no pumps or power. The

CT-2 model platforms

are available for different weight ranges of payload, or supported weight. The

40CT-2 model, while not specifically listed on the Web page, was perfect for

the Clearaudio Ovation turntable used for this review. The platform dimensions

are 18" W x 20" D x 2.7" H, with a weight of about 30 pounds. Different models,

for different payloads, range in price from $4,650 to about $5,250. In my

system, the platform was installed 20" W x 18" D, which placed the adjustment

crank on the 18" left side.

The horizontal frequency of ~1.5 Hz is

achieved at or near the upper limits of the payload range. The vertical

frequency is tunable to 0.5 Hz throughout the payload range. What this means is

that any very low frequency vibrations that are not blocked or absorbed by the

Minus K platform are several orders of magnitude below what your phono

cartridge, or even the best subwoofers, can process.

Full article...

|

|

Technology is winner of a Laser Focus World Innovator

Award

CT-2 Ultra-Thin Low-Height

Tabletop Vibration Isolation Platform

The Compact Tabletop (CT-2)

uses Minus K's patented breakthrough technology allowing for the best

performance on the market in just a 2.5 inch tall isolation platform. This unit

is an upgrade from Minus K's CT-1 and offers better horizontal performance with

additional payload ranges for heavier instruments.

This is the

thinnest, most portable and most user-friendly isolator ever offered that

is capable of delivering this performance.more...:

- Horizontal frequencies are weight dependent.

- Horizontal frequency of ~1.25 Hz is achieved at or near the upper

limits of the payload range.

- At the lower payload weights the horizontal frequency will

increase.

- Vertical frequency is tunable to 0.5 Hz throughout the payload

range.

Pricing & sizes for

CT-2

Press Release for the

CT-2

|

3D Surface Analysis Vibration

Isolation

High-precision, nanometer-level 3D surface

measurement systems can be negatively affected by low-frequency

vibration—distorting imaging and producing inaccurate measurement

readings. |

Manufacturers need to control processes to

produce a consistent, reliable product. Where precision surface engineering is

required, surface measurement may be a key part of maintaining control of the

process, by checking output to see that the process is not outside of

specification.

3D non-contact surface analysis is widely used in the

industry for the measurement of small displacements and surface irregularities.

It delivers the ultimate in high accuracy and repeatable and traceable

measurement. When built into microscopy equipment, employing 3D laser scanning

or structured light, these systems report the surface condition of a product

with more accuracy than any other methodproviding nanometer-level profile

measurements of height, width, angle, radius, volume, and roughness. Such

precision measurement systems allow users to improve product quality and

reliability, and increase manufacturing consistency and production

yields.

Low-Frequency Vibration

When measuring at such high

levels of precision, any instrument can be negatively affected by low-frequency

vibrations generated within a manufacturing facility. These can distort

measurements and impact imaging and measurement data

One company that

has great familiarity with the manufacturing environment and 3D surface

measurements is Keyence Corporation--a leading supplier of sensors, measuring

systems, laser markers, microscopes, and machine vision systems

worldwide.

We have many customers with high-precision 3D measurement

systems operating in high-vibration environments, performing microscopy

evaluation at 30,000 times magnification, looking at nanometer-level surface

features, said Evan Eltinge, Senior Sales Engineer Surface Analysis Team, with

Keyence Corporation of America. At that level of detail, and in that

environment, if measures are taken to reduce vibration it improves the quality

of the data.

Without proper isolation surface measurements occurring at

3,000 to 5,000 times magnification, the vibration could contribute to image

blurring and loss of image quality, continued Eltinge.

Vibration can be

caused by a multitude of factors within a plant; every structure is

transmitting noise. Within the building itself, production machinery, forklift

trucks, the heating and ventilation system, fans, pumps, compressors, and

elevators are just some of the mechanical devices and equipment that create

low-frequency vibration. Depending on how far away the surface measurement

instrumentation is from these vibration sources, and where inside the structure

the instrumentation is locatedwhether on the production floor or in a loftwill

determine how strongly the instrumentation will be influenced.

External

to the building, the equipment can be influenced by vibrations from truck

movement, road traffic, nearby construction, loud noise from aircraft, and even

wind and other weather conditions that can cause movement of the

structure.

Vibration Isolation Options for 3D Surface

Analysis...

Full article...

|

The Moulé Group, at the University

of California/Davis, is interested in the solution processing and patterning of

organic electronic materials for use in devices such as light-emitting diodes,

photovoltaics, transistors, thermoelectric, and chemical sensors. The Group

specifically focuses on using structural and dynamic measurement techniques to

quantify the effects of solution processing and patterning on material

morphology and device architecture.

Tucker Murrey, a doctoral candidate

and published author with the Moulé Group, is actively involved with

researching and designing a scalable optical patterning process for organic

photovoltaic applications.

"Most working organic devices consist of

several layers of material, each having a specific optical and/or electronic

function," said Murrey. "One universal design constraint for complicated device

architectures, like organic field-effect transistors (OFETs), organic

photovoltaics (OPVs) and red-green-blue organic light-emitting diode (OLED)

displays is that they require multiple components patterned laterally and

vertically to operate. Currently, many of these components are comprised of

non-flexible inorganic materials. In order to move towards flexible, all

organic electronic devices, there is a need to develop high precision vertical

and lateral patterning methods that are compatible with solution processing.

mmense efforts in the plastic electronics field have led to

unprecedented progress and continuous improvements in organic photovoltaic

(OPV) performance.

"Given that conventional photolithography technology

techniques are incompatible with polymeric semiconductors, there is a critical

need to develop scalable photopatterning methods capable of laterally

patterning organic semiconducting compounds with sub-micromometer resolution,"

added Murrey. "This patterning process would enable the construction of a

sophisticated OPV architecture designed to increase external quantum

efficiency."

"A scalable process for controlling film topography with

sub-micrometer resolution would represent a substantial development that

enables the advancement of complex organic electronic device architectures,"

continued Murrey.

Photothermal Projection Lithography

The

Moulé Group is working on a series of solution-based methods, one of

which is called Photothermal Projection Lithography for Polymeric

Semiconductors with Sub-diffraction Limited Resolution.

Polymeric

semiconductors combine many of the electrical properties of inorganic

semiconductors with the mechanical flexibility and chemical processability of

organic materials, such as enabling them to be deposited from solution over

large areas, greatly reducing production costs compared to conventional

metallic semiconductors. Developments like this have motivated a rapid increase

in demand for low-cost, high-throughput, and high-resolution fabrication

techniques.

Organic semiconductors are non-metallic materials that

exhibit semiconductor properties, whose building blocks are polymers made up of

carbon and hydrogen atoms. These conductive polymers are, essentially,

electrical insulators, but become conducting when charges are either injected

from electrodes or by photoexcitation, or doping the intentional introduction

of impurities into an intrinsic semiconductor for the purpose of modulating its

electrical, optical, and structural properties.

"Over the past year I

have been upscaling an optical patterning process that our group developed to

make micro-scale electronic devices with these materials," expressed Murrey.

"The overall pattern area was limited to less than one square millimeter. Now

we are trying to upscale the overall patterning area to about one square

centimeter."

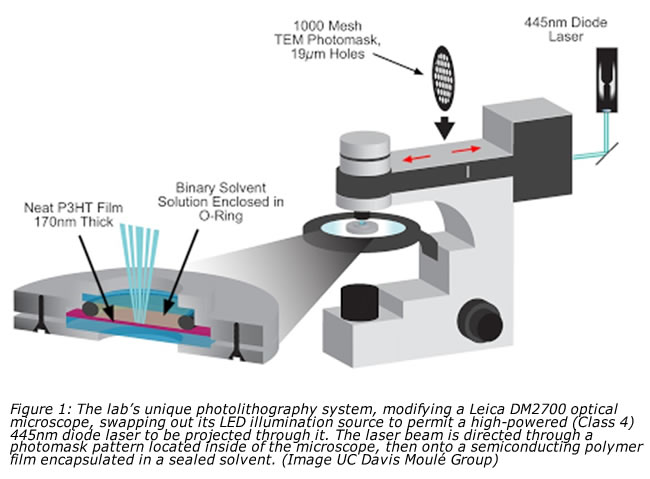

Murrey designed a unique lab-scale photolithography system,

modifying a Leica DM2700 optical microscope, swapping out its LED illumination

source to permit a high-powered (Class 4) 405nm diode laser to be projected

through it. Built into the system is a laser beam expander, collimating lens,

and an optical speckle remover.

|

Full article...

|

|

|

Professor Holger Müller's Group at UC

Berkeley is focused on advancing experimental quantum technology to push the

sensitivity of experiments to new levels, and to perform precision measurements

of fundamental constants. The groups work uses methods from atomic, molecular

and optical physics. One project is the development of a transportable,

multi-axis atom interferometer, named miniG.

MiniG was designed to

research how quantum interference can be used to measure gravity outside of the

laboratory. When cooled to just above absolute zero, the atoms form the focus

of a portable quantum gravimeter.

Gravimeters, used to measure

gravitational acceleration, have been successfully applied for metrology,

geology and geophysics. MiniG uses an atom interferometer to measure the effect

of gravity on clouds of atoms that are first trapped and cooled. Interferometry

inherently depends on the wave nature of the object. Particles, including

atoms, can behave like waves. Atom interferometers measure the difference in

phase between atomic matter waves along different paths.

We use atoms

that are laser-cooled to millionths of a degree above absolute zero, said

Xuejian Wu, a post-doctoral scholar, involved in the development of miniG at

the Müller Group. With pulses of light, we drive each atom into a quantum

superposition of having been kicked with the momentum of photons, or not

kicked. The atoms, in two places at one time, are in a superposition of

recoiling backwards or staying still. By manipulating the state of the atoms

using one of two types of such light pulses, we steer the matter waves' paths

and recombine the matter waves at the end of the experiment.

Atom

interferometry has become one of the most powerful technologies for precision

measurements, and atomic gravimeters, based on atom interferometry, are

extremely accurate and have long-term stability.

Current atom

interferometers, however, are too complicated to operate in a miniature package

or under field conditions. Berkeleys mini-G was engineered to resolve this

issue.

In this project, we are developing a mobile atom interferometer

using a single-diode laser system and a pyramidal magneto-optical trap,

continued Wu. This allows the device to be smaller, simpler and more robust

than conventional atom interferometers.

Vibration

Isolation

Measurements of atomic precision require

isolation from ambient vibrations coming from internal and external sources. As

measurements are being done at a smaller and smaller level, those vibrations

that are present will start to dominate, and the need for more effective

isolation increases.

Although the Müller Groups research

laboratory is situated in the basement of a building on the Berkeley campus, it

is still influenced by vibrations from the buildings HVAC system.

For

several years now we have been using

Negative-Stiffness vibration isolation for our

research projects, continued Wu.

Full article...

|

|

|

|

|

|