|

|

Newsletter March 2021 | Menu of Newsletters

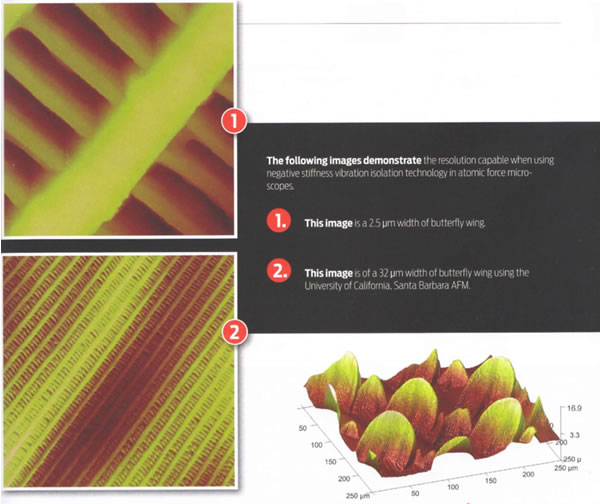

Here is an image of 250 µm width

of butterfly wing using University of California, Santa Barbara AFM with

negative-stiffness

vibration isolation.

(Lagacy 2013 article) With its

development in 1986, and subsequent commercial introduction in 1989, the

atomic force microscope

(AFM) is one of the foremost tools for imaging and measuring

materials and cells on the nanoscale. Revealing sample details at the atomic

level, with resolution on the order of fractions of a nanometer, the AFM is

instrumental for imaging an array of applications, such as defining surface

characterizations, lithography, datastorage, and manipulation of atoms and

nano-sized structures on a variety of surfaces.

The need for more

precise vibration isolation with AFM, though, is becoming critical as

resolutions continue to bridge from micro to nano.

AFM

systems are extremely susceptible to vibrations from the environment. When

measuring a very few angstroms or nanometers of displacement, an absolutely

stable surface must be established for the instrument. Any vibration coupled

into the mechanical structure of the instrument will cause vertical and

horizontal noise and bring about a reduction in the ability to measure with the

highest resolution.

The vertical axis is the most sensitive for AFMs,

but these microscopes are also quite sensitive to vibrations in the X and Y

axes.

The atomic force microscope uses a sharp tip (probe), with a

radius of curvature on the order of nanometers attached to the end of a tiny

cantilever used to scan across a sample surface to image its topography and

material properties. When the tip is brought into proximity of a sample

surface, forces between the tip and the surface lead to a deflection of the

cantilever This deflection is typically recorded using a laser beam that is

reflected from the top surface of the cantilever to a photosensitive detector.

The resultant position change of the cantilever allows characteristics such as

mechanical, electrostatic, magnetic, chemical and other forces to be precisely

measured by the AFM. These characteristics are displayed in a three-dimensional

surface profile of the sample (in the X, Y and Z axes)an advantage that the AFM

can provide compared to other microscopy techniques, such as the scanning

electron microscope (SEM) which delivers a two-dimensional image of a sample

(in the X and Y axes).

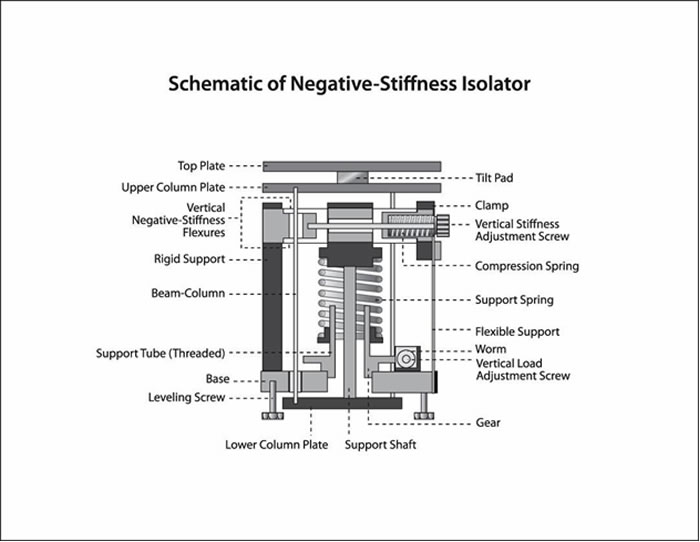

Minus K BM-1

Isolator.

Full article...

|

|

Featured Product: BM-1 Bench Top

Vibration Isolation Platform

- Vertical Load Adjustment

Crank - Simple manual adjustment compensates for changes in vertical load.

- Vertical Load Adjustment

Indicator - Easily determine optimum setting using this simple visual

indicator.

- Vertical Stiffness

Adjustment Screw - Dial in Guaranteed 1/2 Hz or less Vertical natural frequency

using this simple adjustment.

- Isolator Dimensions: 24" W

x 22.5" D x 9" H (610mm W x 572mm D x 216mm H).

- Weight: Approximately 90

lb (41 kg) - Dimensions - an additional 0.675" taller than the above units

Vertical natural frequency of

1/2 Hz or less can be achieved over the entire load range.

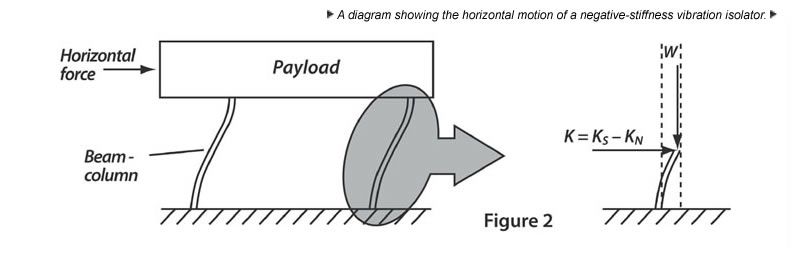

Horizontal

natural frequency is load dependent. 1/2 Hz or less can be achieved at or near

the nominal load.

Specifications

(pdf)

Pricing

|

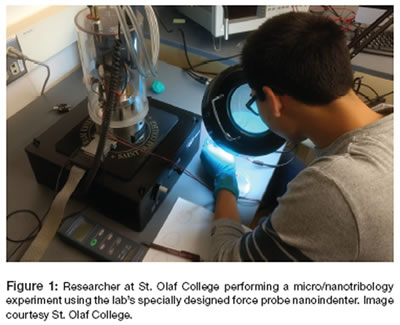

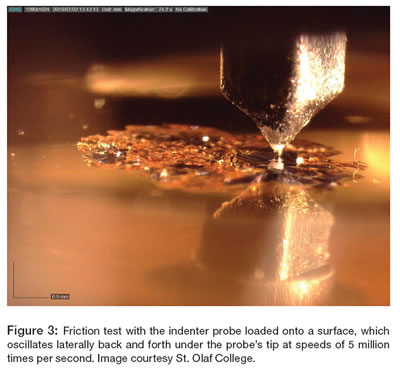

Abstract: Researchers in the Physics

Department of St. Olaf College are using a uniquely designed, integrated

nanoindenter-quartz microbalance apparatus to bridge the gap between the

fundamental science of friction and the engineering of practical

micromechanical systems. This level of micro-research requires extreme

stability for the microbalance instrumentation. Since 2001, the lab has used

negative-stiffness vibration isolation to achieve a high level of isolation in

multiple directions, custom tailoring resonant frequencies to 0.5 Hz vertically

and horizontally.

Introduction: Scientists do not fully

understand what causes friction and wear between two surfaces at the molecular

level. When designing a micromechanical system, the fundamental machine parts

of gears, hinges, pistons, gimbals, and suspended beams that flex are included.

Basic motions that are the essence of mechanics rely on these materials having

durability and low or controllable friction. Mastering these forces that occur

on small-scale surfaces of micromachines is a considerable challenge. When the

mechanical parts are very small, their properties are dominated by minute

surface forces that macroscopic machines are not sensitive enough to detect.

This raises entirely new questions about how to maintain minute components and

to keep them moving and protected from wear or breakage.

Silicon Uniformity:

Engineers have relied on extremely thin

lubricant films to reduce friction and to keep parts moving inside tiny

silicon-constructed microelectromechanical systems (MEMS). But these films have

not been sufficiently effective in micromachines, which rely on relatively

fast-moving parts that are in contact with each other, such as gears, gimbals,

and pistons. Since the early 1980s, with the introduction of the first

micromechanical machines, the vision has been to batch-fabricate these devices

as silicon chips to link with circuitry that can be connected wirelessly.

However, these small silicon machines often disintegrate after just a few hours

of operation. This technology has, for some time, been struggling to make it to

the marketplace. Decades of research in both academia and business has been

undertaken to understand friction and wear well enough at these micro- and

nano-scales to effectively lubricate and provide wear protection.

New Research Methodology:

Professor Brian Borovsky,

Associate Professor in the Physics Department at St. Olaf College in

Northfield, MN, has been researching micro/nanotribology for over two decades

[14]. He has pioneered friction research as applied to very tiny

micromechanical machines, having developed state-of-the-art instrumentation and

a process that tests frictional properties of surfaces coated with ultrathin

lubricants. His is one of the few labs that can measure friction of

micromachine surfaces sliding past each other at very high speeds that approach

1m/s.

While equipped with scanning electron (SEM) and atomic force

microscopy (AFM) for analysis of surfaces, the labs focus instrumentation is a

specially designed force probe nanoindenter in conjunction with a quartz

microbalance...

Full article...

|

Commercial Micro Manufacturing -

Dec.2020

The need for nano- precision has became

increasingly important in many fields of research and manufacturing, inducing

microelectromcs fabrication, laser/optical system applications and biological

research. This has meant that so too has the need for vibration Isolation

technology that better facilitates the operation of sensitive Instrumentation

such as

atomic force microscopes, scanning tunneling

microscopes,

laser interferometers and optical

profilers.

Once the mainstay for stabilizing academia's

and Industry's most critical microenginering instrumentation, pneumatic (gas or

air pressurized) vibration Isolation tables are today proving unsatisfactory in

isolating disruptive

low-frequency vibrations. There is a growing trend

for locating sensitive instrumentation in building to locations that are

subject to extremely high levels of vibration and this is a significant

stumbling block for pneumatic vibration isolation tables, meaning alternative

vibration isolation solutions are required.

Vibration

sources

Nano-level instrumentation is sensitive to extremely small

payload vibrations that can be caused by a multitude of factors. Every

structure (building) transmits vibrations from Internal and external sources In

a building, heating and ventilation systems, fans, pumps and elevators are Just

some of the mechanical devices that create vibrations. Outside a building,

adjacent road traffic, nearby construction, aircraft and even wand and other

weather conditions all create vibrations How strongly the instrumentation is

influenced depends on where it is in the building and how far away it is from

the vibration sources.

Isolation for vibration critical applications

Over the

past 25 years, two technologies have gained prominence for their ability to

Isolate vibrations Influencing nano-level Instrumentation, namely active

vibration isolation (also known as electronic-force cancellation) and

negative-stiffness vibration isolation {also known as passive vibration

isolation).

Both active and negative-stiffness vibration isolation are

uniquely equipped for applications where structures smaller than a micrometre

need to be produced or measured. These technologies provide functionality that

is typically not achievable with pneumatic vibration isolation

tables.

Full article: Comparing systems...

|

You might have thought, maybe for only a

few moments, that your

audio system was

sounding especially good. With that feeling, you would have rated the sound a

top score of "10". Then those magical moments ended and your system returned to

it's normal - but still good - performance level. Well, folks, the Minus K

CT-2 Isolation

Platform could raise your system score to an "11" and keep it there! Highly

recommended for systems that are already high performance and where you want to

coax the maximum performance from your audio investment....

Dr. David L.

Platus is President and Founder and is the principal inventor of the

technology. He earned a B.S. and a Ph.D. in Engineering from UCLA, and a

diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to

founding Minus K® Technology he worked in the nuclear, aerospace and

defence industries conducting and directing analysis and design projects in

structural-mechanical systems. He became an independent consultant in 1988. Dr.

Platus holds over 20 patents related to shock and vibration

isolation.

Ultra-Thin 2.7" High

CT-2 Product

Attributes:

- Isolation performance is typically 10 to 100 times

better than air systems

- No air or electric power is

required

- Nothing to wear out

- No

maintenance

A complete description of the patented

Negative-stiffness design can be found on the

Technology page of the manufacturers Web site. The Minus K platform is

completely silent and requires no pumps or power. The

CT-2 model platforms

are available for different weight ranges of payload, or supported weight. The

40CT-2 model, while not specifically listed on the Web page, was perfect for

the Clearaudio Ovation

turntable used for

this review. The platform dimensions are 18" W x 20" D x 2.7" H, with a weight

of about 30 pounds. Different models, for different payloads, range in price

from $4,650 to about $5,250. In my system, the platform was installed 20" W x

18" D, which placed the adjustment crank on the 18" left side.

The

horizontal frequency of ~1.5 Hz is achieved at or near the upper limits of the

payload range. The vertical frequency is tunable to 0.5 Hz throughout the

payload range. What this means is that any very low frequency vibrations that

are not blocked or absorbed by the Minus K platform are several orders of

magnitude below what your phono cartridge, or even the best subwoofers, can

process.

Full article...

|

3D Surface Analysis Vibration

Isolation

High-precision, nanometer-level 3D surface

measurement systems can be negatively affected by low-frequency

vibration—distorting imaging and producing inaccurate measurement

readings. |

Manufacturers need to control processes to

produce a consistent, reliable product. Where precision surface engineering is

required, surface measurement may be a key part of maintaining control of the

process, by checking output to see that the process is not outside of

specification.

3D non-contact surface analysis is widely used in the

industry for the measurement of small displacements and surface irregularities.

It delivers the ultimate in high accuracy and repeatable and traceable

measurement. When built into microscopy equipment, employing 3D laser scanning

or structured light, these systems report the surface condition of a product

with more accuracy than any other methodproviding nanometer-level profile

measurements of height, width, angle, radius, volume, and roughness. Such

precision measurement systems allow users to improve product quality and

reliability, and increase manufacturing consistency and production

yields.

Low-Frequency Vibration

When measuring at such high

levels of precision, any instrument can be negatively affected by low-frequency

vibrations generated within a manufacturing facility. These can distort

measurements and impact imaging and measurement data

One company that

has great familiarity with the manufacturing environment and 3D surface

measurements is Keyence Corporation--a leading supplier of sensors, measuring

systems, laser markers, microscopes, and machine vision systems

worldwide.

We have many customers with high-precision 3D measurement

systems operating in high-vibration environments, performing microscopy

evaluation at 30,000 times magnification, looking at nanometer-level surface

features, said Evan Eltinge, Senior Sales Engineer Surface Analysis Team, with

Keyence Corporation of America. At that level of detail, and in that

environment, if measures are taken to reduce vibration it improves the quality

of the data.

Without proper isolation surface measurements occurring at

3,000 to 5,000 times magnification, the vibration could contribute to image

blurring and loss of image quality, continued Eltinge.

Vibration can be

caused by a multitude of factors within a plant; every structure is

transmitting noise. Within the building itself, production machinery, forklift

trucks, the heating and ventilation system, fans, pumps, compressors, and

elevators are just some of the mechanical devices and equipment that create

low-frequency vibration. Depending on how far away the surface measurement

instrumentation is from these vibration sources, and where inside the structure

the instrumentation is locatedwhether on the production floor or in a loftwill

determine how strongly the instrumentation will be influenced.

External

to the building, the equipment can be influenced by vibrations from truck

movement, road traffic, nearby construction, loud noise from aircraft, and even

wind and other weather conditions that can cause movement of the

structure.

Vibration Isolation Options for 3D Surface

Analysis...

Full article...

|

The Moulé Group, at the University

of California/Davis, is interested in the solution processing and patterning of

organic electronic materials for use in devices such as light-emitting diodes,

photovoltaics, transistors, thermoelectric, and chemical sensors. The Group

specifically focuses on using structural and dynamic measurement techniques to

quantify the effects of solution processing and patterning on material

morphology and device architecture.

Tucker Murrey, a doctoral candidate

and published author with the Moulé Group, is actively involved with

researching and designing a scalable optical patterning process for organic

photovoltaic applications.

"Most working organic devices consist of

several layers of material, each having a specific optical and/or electronic

function," said Murrey. "One universal design constraint for complicated device

architectures, like organic field-effect transistors (OFETs), organic

photovoltaics (OPVs) and red-green-blue organic light-emitting diode (OLED)

displays is that they require multiple components patterned laterally and

vertically to operate. Currently, many of these components are comprised of

non-flexible inorganic materials. In order to move towards flexible, all

organic electronic devices, there is a need to develop high precision vertical

and lateral patterning methods that are compatible with solution processing.

mmense efforts in the plastic electronics field have led to

unprecedented progress and continuous improvements in organic photovoltaic

(OPV) performance.

"Given that conventional photolithography technology

techniques are incompatible with polymeric semiconductors, there is a critical

need to develop scalable photopatterning methods capable of laterally

patterning organic semiconducting compounds with sub-micromometer resolution,"

added Murrey. "This patterning process would enable the construction of a

sophisticated OPV architecture designed to increase external quantum

efficiency."

"A scalable process for controlling film topography with

sub-micrometer resolution would represent a substantial development that

enables the advancement of complex organic electronic device architectures,"

continued Murrey.

Photothermal Projection Lithography

The

Moulé Group is working on a series of solution-based methods, one of

which is called Photothermal Projection Lithography for Polymeric

Semiconductors with Sub-diffraction Limited Resolution.

Polymeric

semiconductors combine many of the electrical properties of inorganic

semiconductors with the mechanical flexibility and chemical processability of

organic materials, such as enabling them to be deposited from solution over

large areas, greatly reducing production costs compared to conventional

metallic semiconductors. Developments like this have motivated a rapid increase

in demand for low-cost, high-throughput, and high-resolution fabrication

techniques.

Organic semiconductors are non-metallic materials that

exhibit semiconductor properties, whose building blocks are polymers made up of

carbon and hydrogen atoms. These conductive polymers are, essentially,

electrical insulators, but become conducting when charges are either injected

from electrodes or by photoexcitation, or doping the intentional introduction

of impurities into an intrinsic semiconductor for the purpose of modulating its

electrical, optical, and structural properties.

"Over the past year I

have been upscaling an optical patterning process that our group developed to

make micro-scale electronic devices with these materials," expressed Murrey.

"The overall pattern area was limited to less than one square millimeter. Now

we are trying to upscale the overall patterning area to about one square

centimeter."

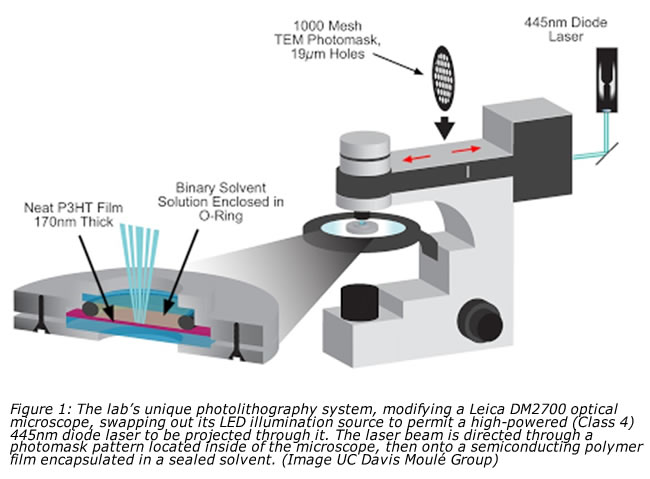

Murrey designed a unique lab-scale photolithography system,

modifying a Leica DM2700 optical microscope, swapping out its LED illumination

source to permit a high-powered (Class 4) 405nm diode laser to be projected

through it. Built into the system is a laser beam expander, collimating lens,

and an optical speckle remover.

|

Full article...

|

|

|

|

|

|