|

|

Newsletter November 2021 | Menu of Newsletters

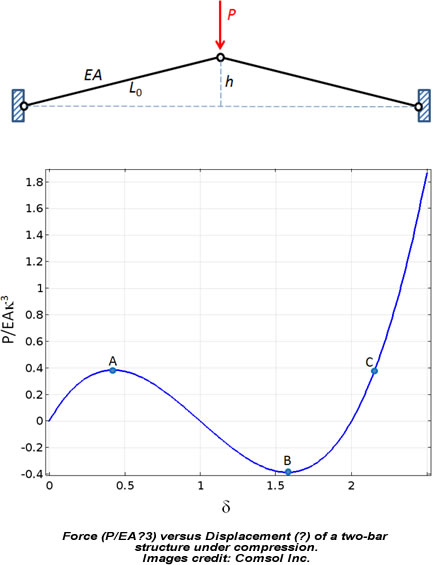

Notice that between points A and B,

displacement is increasing while force is decreasing. Thus, the

structure’s stiffness is negative in that region.

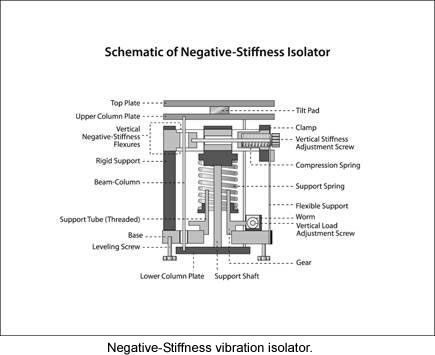

Negative-stiffness vibration isolators

consist of a horizontal isolator and a vertical isolator connected in series.

To counter motions that involve rotation (pitch and roll), a tilt motion pad

can also be connected in series with the horizontal and vertical isolators.

The horizontal isolator consists of two fixed-free vertical beams

(columns) supporting a weight. The weight imparts both eccentric (off-axis)

axial compressive load and a transverse bending load. This phenomenon is

referred to as the beam-column effect and causes the lateral bending stiffness

of the beams to decrease. In effect, the isolator is acting as a horizontal

spring with a negative-stiffness mechanism.

The horizontal isolator is designed to

take advantage of the beam-column effect, allowing it to act like a

negative-stiffness mechanism.

Vertical motion is addressed using two

horizontal flexures loaded in compression, which form a negative-stiffness

mechanism. The flexures are supported at their outer ends and connected to a

stiff spring at their inner ends. The stiffness of the isolator is determined

by the design of the flexures and by their compressive load.

Two flexures, fixed at their outer ends

and connected to a spring at their inner ends, form a negative-stiffness

mechanism that isolates equipment from vertical motion due to

vibrations.

Full article...

|

|

Featured Product: WS-4 Compact Vibration Isolation

Table

- Vertical natural frequency of 1/2 Hz or less can be achieved over

the entire load range.

- Horizontal natural frequency is load dependent. 1/2 Hz or less can

be achieved at or near the nominal load.

- Horizontal natural frequency is load dependent. 1/2 Hz or less can

be achieved at or near the nominal load.

- Dimensions: 24" W x 24" D x 23" H

(610mm W x 610mm D x 533mm

H)

A cost

effective vibration isolation table for weight loads up to 1000 lb. and 1/2 Hz

performance vertical and horizontal. A cost

effective vibration isolation table for weight loads up to 1000 lb. and 1/2 Hz

performance vertical and horizontal.

The stand has been designed with a

damped Phenolic top which includes locating holes for the leveling feet of the

BM-1 and

BM-4.

Pricing & Specifications

|

Close-up of a stylus and LP record

vinyl grooves

"Vinyl remains unsurpassed for

reproducing music,” said Mark Döhmann, Founder of Döhmann Audio.

To convey vinyls rich, nuanced potential a turntable must have precise speed

control and operate without producing mechanical or electronic noise. The goal

is an uncompromised signal emerging from a silent background, resulting from

precisely designed construction that eliminates noise and gives precision speed

control for ideal playback.

This goal has been very closely

approximated with the release of the Helix One and Helix Two turntables,

representing a breakthrough in analog playback design and execution. These

turntables are a showcase for micro-signal architecture, a new way of thinking

borne from the world of ultra-precision sub-atomic research, where the removal

of unwanted vibration is critical to achieving precision results.

The

Helix One and Helix Two turntables reward the listener with the closest

facsimile to master tape yet realized. Their specifications demand the ultimate

in noise suppression and vibration isolation systems, allowing the turntables

and pick-up arms to deliver the micro-signals buried in the vinyl grooves of

LPs.

Every aspect of the turntables' design requires the preservation

of the micro-signals found in the grooves of the LP to be retrieved with as

little modification and distortion as physically and electronically possible,

added Döhmann. The turntables incorporate a number of engineering advances

to deliver the lowest resonance profile for any pickup arm and LP

combination.

These engineering advances include: a) mechanical crossover

technology; b) a tri-modal platter system; c) an edge-damping ring; d) a tone

arm damping system; e) resonance-tuned suspension; f) a diamond-like coating,

amorphous material-bearing friction modifier; g) high-torque, adjustable-drive

speed selections; and h) a velocity adjustment lock.

But what

contributes to making the Helix One and Helix Two turntables truly unique is

their highly precise, fully-integrated vibration isolation system.

The Need For Vibration

Isolation

Vibration isolation in the playback process of high-end audio

systems is crucial. Any external vibration, no matter how slight, even someone

walking near the turntable or vibration from floor-mounted speakers, is sensed

by the turntables stylus and affects the sound being played back from the

record. Capacitors, resistors, transistors, tube amplifiers and other

electronic components are likewise sensitive to vibration.

Analog audio

is a very detailed and information rich storage and retrieval mechanism,

continued Döhmann. The enemy of retrieval information is vibration, which

can modulate with the needle as it works its way through the groove. If you can

remove exterior vibration and allow the needle to operate in an optimally quiet

method or platform, then you will get more information out because your noise

is much lower.

Full article...

More at our Audio & Turntable Vibration Isolation

Applications page...

|

(2016 Legacy Article) The tunable

microwave-frequency alternating current scanning tunneling microscope (ACSTM)

has opened the possibility of recording local spectra and local chemical

information on insulator surfaces, much like the conventional scanning

tunneling microscope (STM) has done for metals and

semiconductors..

Spectroscopy in the microwave frequency range enables

unrealizable measurements on conducting substrates, such as the rotational

spectroscopy of a single adsorbed molecule. Developed in the early 1990s by

Professor Paul Weiss, the nano-pioneering Director of the Weiss Group, a

nanotechnology research unit of UCLAs California NanoSystems Institute, the

ACSTMs single-molecule measurement techniques have illuminated unprecedented

details of chemical behavior, including observations of the motion of a single

molecule on a surface, and even the vibration of a single bond within a

molecule. Such measurements are critical to understanding entities ranging from

single atoms to the most complex protein assemblies.We use molecular design,

tailored syntheses, intermolecular interactions and selective chemistry to

direct molecules into desired positions to create nanostructures, to connect

functional molecules to the outside world, and to serve as test structures for

measuring single or bundled molecules, said David McMillan, Lead Technician at

the Weiss Group.

Critical to understanding these variations has been

developing the means to make tens- to hundreds-of-thousands of independent

single-molecule measurements in order to develop sufficiently significant

statistical distributions, while retaining the heterogeneity inherent in the

measurements.

Vibration isolation

To achieve

these nano-level chemical and spectroscopic data sets, the ACSTM must be

positioned in an ultra-stable operating environment, one free of low-frequency

vibrations.The lab was using almost exclusively optical tables on pneumatic

isolation, said McMillan.One of our big problems has been space constraint. We

needed smaller pneumatic optical tables to fit. But as the air tables get

smaller, their vibration isolation performance diminishes.

Full article... |

The compound microscope has evolved from an

instrument providing simple contrast viewing, into super-resolution systems

capable of sub-diffraction accuracy. Its two platforms, upright and inverted,

can be found in most laboratories doing cellular research, such as in biotech

and pharmaceutical. Upright microscopes are used for viewing glass slides, and

inverted for viewing live cells in Petri dishes. Despite its imaging advances,

the basic architecture of the compound microscope has not substantially been

modified in centuries.

This has now changed, with the recent release of

the Revolve hybrid compound microscope, developed by Echo Laboratories (Echo),

which has set a new precedent in microscope usability and design. The Revolve

combines the full functionality of both upright and inverted microscopes in one

instrument, and can switch between the two imaging modes relatively swiftly and

easily. This gives the flexibility to view many types of samples with one

microscope to a level of 300 350 nanometers resolution.

“More than 70 percent of labs end up

having both inverted and upright microscopes,” said Jeff Huber, Director

of Sales for Echo Laboratories. “But both uprights and inverts use similar

objectives, illuminators, position systems and cameras. Why duplicate all of

these expensive components? And why take up valuable lab space with two

instruments? So, Echo Laboratories engineered a way to merge these two systems

into one unified instrument, which is the Revolve

microscope.”

Brightfield, Phase Contrast and Epifluorescence

Imaging with iPad and Wireless Upload

his is a compound, infinity-path

microscope, with applications for brightfield, phase contrast, and

epi-fluorescence imaging. Current glass selection includes the entire line of

Olympus objectives. Due to the unique nature of the upright/inverted

combination, both a high-NA and long-working-distance transmitted-light

condensers are available to support phase and brightfield. A high-accuracy

locking mechanism is used to securely hold the condenser assembly in place,

while still allowing for easy removal by a single lever.

Full article... |

Since the release of the first commercial

atomic force microscope (AFM) about 30 years ago, technology advances have

steadily been implemented to improve their performance. Now, the most recent

advance in ambient-temperature AFMs is making them more compact, portable and

user-friendly, which is enabled by Negative-Stiffness vibration isolation.

The atomic force microscope (AFM) has become one of the foremost tools

for imaging and measuring materials and cells on the nanoscale. Revealing

sample details at the atomic level, with resolution on the order of fractions

of a nanometer, the AFM is instrumental for imaging an array of applications,

such as defining surface characterizations, lithography, data storage, and

manipulation of atoms and nano-sized structures on a variety of

surfaces.

The AFM utilizes a sharp tip (probe) with a radius of

curvature on the order of a few nanometers attached to the end of a tiny

cantilever used to scan across a sample surface to image its topography and

material properties. When the tip is brought into proximity of a sample

surface, forces between the tip and the surface lead to a deflection of the

cantilever. This deflection is recorded using, typically, a laser beam that is

reflected from the top surface of the cantilever to a photo-sensitive detector.

The resultant change of position of the cantilever/probe/tip permits

characteristics such as mechanical, electrostatic, magnetic, chemical and other

forces to be precisely measured by the AFM. These characteristics are displayed

in a three-dimensional surface profile of the sample (in the X, Y and Z axes),

an advantage that the AFM can provide compared to other microscopy

techniques.

Although AFM technology has advanced considerably, its

benefits have not always been easily accessible for researchers requiring AFM

adaptability, portability. Nor have AFMs been adequately accessible in

nanotechnology student laboratories, because of lack of student skill in their

operation, and budget limitations on the number of AFMs at their

disposal.

A More Portable, More User-Friendly

AFM

These inhibitions have now been mitigated by a relatively new

compact, portable and user-friendly ambient-temperature AFM. Developed by

NanoMagnetics Instruments, a leading manufacturer of scanning probe microscopes

for low-temperature applications, the ezAFM+ atomic force microscope is a

benchtop instrument designed for short learning times, quick setup, and ease of

transport.

Full article... |

|

|

|

|

|

|