|

|

Newsletter October 2024 | Menu of

Newsletters

| |

|

|

|

NASA’s Lunar Atmosphere and Dust

Environment Explorer (LADEE), pronounced Laddie, was a robotic mission

launched in 2013 that orbited the moon to gather detailed information about the

structure and composition of the thin lunar atmosphere, and the first-ever

Lunar Laser Communications Demonstration (LLCD). The LLCD used lasers, not

radio waves, like other spacecraft that have flown beyond close-Earth orbit

have used, to communicate with controllers on Earth allowing the spacecraft to

communicate at broadband speeds with the ground. |

|

The probe was approximately

7.7ft x 4.75ft x 4.75ft, weighing 383kg (844 lb). The probe took about 30 days

to get to the moon. LADEE then went through a checkout period for another 30

days. After that, the probe conducted a 100-day science mission and was even

able to extend its mission for an additional month..

Once LADEEs mission

was completed, NASA intentionally impacted the probe into the far side of the

moon, away from historically important sites like the Apollo landing zones.

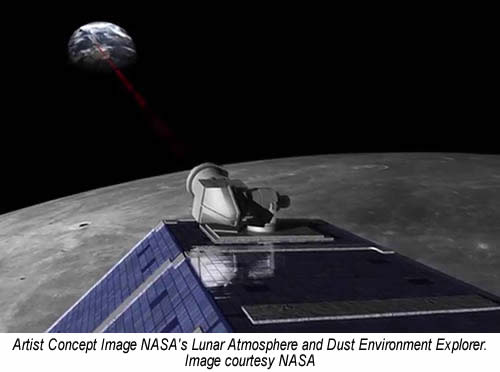

Lunar Laser Communications Demonstration

The LLCD was a

project undertaken by MIT Lincoln Laboratory, NASA's Goddard Space Flight

Center, and the Jet Propulsion Laboratory. It was NASAs first attempt to

demonstrate optical communications between a lunar orbiting spacecraft and

Earth-based ground receivers.

|

|

All prior communications with spacecraft

beyond close-Earth orbits required spacecraft to have small, low-mass,

low-power radio transmitters and giant satellite dishes on Earth to receive

their messages. LLCD was an alternative process to replace traditional radio

communications with specialized lasers and laser detection units to send

information between lunar orbit and three receiving stations in the U.S. and

Spain.

LLCD demonstrated error-free communication from the moon,

including during broad daylight and even when the moon was within 3° of the

sun, as seen from Earth. LLCD also operated error-free when the moon was less

than 5° above the horizon, as seen from the ground station, which showed

that wind and atmospheric turbulence didnt significantly impact the system.

LLCD was even able to communicate through thin cirrus clouds.

The 30-day

test was a much more comprehensive check of its utility for all-purpose

communication. Rather than simply downloading a pre-arranged file, NASA used

the device for real communication with LADEE, and real collection of data.

While all LADEEs science data went to the ground via radio frequency (RF) link,

the data sent by the LLCD test was verified against the RF data, demonstrating

the feasibility of laser communication uplink/downlink for future

missions.

The LLCD used a pulsed laser beam to transmit data over the

239,000 miles from the moon to Earth at a record-breaking data-download speed

of 622 Megabits per second (Mbps), versus 75Mbps. This download speed was more

than 6x faster than the speed achieved by the best radio system ever flown to

the moon and would normally take several days to download.

LLCD also

demonstrated a 20Mbps uplink, which was used to loop back error-free

high-definition video to and from the moon, important for future human

exploration missions, and also provided simultaneous centimeter-class precision

ranging to the spacecraft, which can be used to improve the gravity models of

planetary bodies.

|

|

The testing looked at more than raw download

speed, prioritizing signal reliability and accuracy, along with possible

distance effects. LLCD worked well even at extremely oblique angles, when the

satellite was near the Earth’s horizon and its signals were forced to move

through the thickest portions of the atmosphere. The laser signal could be read

without error even in broad daylight and through light clouds.

In

addition to this lack of error, the LLCD was able to switch from one ground

station to the next as the Earth turned, in a manner that NASA compared to how

a mobile phone network operates, and the system did so without human

intervention. The system could even lock on to the ground stations without

using a radio signal.

The real breakthrough of the LLCD demonstration,

however, was the spectacular success of its essentially flawless operations,

allowing the system to return real, high-value science data from LADEEs

instruments investigating the moons environment and showing the promise of

laser communication for future missions.

The downside for the future is

range. Simply boosting power to the laser to make it cohere better over a

longer distance is a losing game. A more reasonable solution, and one NASA is

working toward, is the Lunar Communications Relay Demonstration (LCRD). This

would see NASA pepper space with laser-routers to read and re-transmit laser

signals from a new transmitter. LCRD is aboard the U.S. Department of Defenses

Space Test Program Satellite 6 (STPSat-6) launched December

2021.

Article

continued...

|

|

|

|

|

|

|

Only 2.7"

High

The NEW

CT-10

Ultra-Thin Low-Height Tabletop

Vibration Isolation

Platform

|

|

The Compact Tabletop

(CT-10)uses

Minus K's patented breakthrough technology allowing for the best performance on

the market in just a 2.7 inch tall; approximately 12.6 inches deep and wide

isolation platform. This unit is as tall as Minus K's CT-2 and offers similar

horizontal performance with additional payload ranges for smaller

instruments..

This completely passive mechanical isolator offers 10-100

times better performance than a full size air table. It does this without any

air or electricity!

This vibration isolation platform is extremely easy

to use and offers our signature 0.5 Hz vertical natural frequency and ~1.5 Hz

horizontal natural frequency. There are only two adjustments. The

CT-10

is ideal for all types of benchtop microscopes

This is the thinnest,

most portable and most user-friendly isolator ever offered that is capable of

delivering this performance.

See

Weight & Pricing Details...

|

|

|

|

|

| |

|

|

Announcing

the 2025 Minus K Technology Educational $25,000 Giveaway to

U.S. Colleges

and Universities

Minus K

Technology, Inc. is giving away $25,000* worth of patented vibration

isolators to colleges within the United States.

Your college could

receive one of our superior performing negative-stiffness low-frequency

vibration isolators, which use no air or electricity and are currently being

used for biology, neuroscience, chemistry, crystal growing, physics, audio

reproduction and many other fields.

If you have an Atomic Force

Microscope (AFM), Electron Microscope, Interferometer, Laser Optical System,

Micro Hardness Tester, or any other special equipment that would be assisted by

our vibration isolation, simply complete the giveaway submission form and send

it back to

edgiveaway@minusk.com.

If you're one of the top applicants, we'll send you one of these free vibration

isolators to assist you with your research.

Submission deadline

for applications is February 28, 2025.

*More...

*$25,000 of

retail products will consist of at least one each of the following models of

Negative-Stiffness vibration isolators: WS-4, BM-1, BM-4, BM-8, BM-10 and CM-1.

Based on the information provided within grant forms Minus K may substitute

different models to best accommodate the application and payload

needs. |

|

|

|

|

|

2023-2024 Winners: Minus K Technology's

Vibration Isolator Educational Giveaway

to U.S. Colleges and

Universities

Wabash College - Physics Department

The vibration isolator will be used with their Zeiss 508 Microscope to

conduct experiments utilizing high magnification to image Brownian motion in

time-lapse imaging of chemical precipitation material formation.

Kent University - Physics Department

The vibration isolator will be used for a magnetic tweezer instrument

to be built on it. Fast video imaging (several hundred images per second) is

used to measure the changes in the depth of glass beads (of a few micrometer

diameter).

Texas Christian University –

Physics & Astronomy Department

The vibration isolator to be used

with their 6-digit RADWAG XA 21.4Y.M microscale to improve precision of small

mass measurements down to 1 microgram.

Indiana University – Physics

Department

The vibration isolator will be used to for dynamic

micro-optical coherence tomography of the heterogeneous intracellular motion

present in living cells and tissues. |

Check out previous Educational

Giveaway winners: Check out previous Educational

Giveaway winners: |

|

|

|

|

Today's Medical

Developments – June 2024

Negative-stiffness vibration isolation, enabling

research

into the sub-microns

From the discovery

of exoplanets to the characterization of nanoparticles, much of our most

advanced technological research relies on ultra-sensitive vibration isolation

systems. The best of these is capable of isolating sub-Hertz frequencies and

enables precision research at the sub-atomic level. On the forefront of this

enabling technology is Negative-Stiffness vibration isolation developed by

Minus K Technology

Minus

K Technology principals (L to R) Steve Varma, Erik Runge and Jason Blain,

enable companies, academia and government research laboratories to push the

boundaries of advanced technology.

|

|

As the need for nano-precision has become

increasingly important in many fields of research and manufacturing – such

as microelectronics fabrication, laser/optical system applications, life

sciences, materials, aerospace and biological research – so has the need

to implement vibration isolation technology for stabilizing academia’s and

industry’s most critical instrumentation to facilitate operation under

extremely precise requirements operating at atomic-scale

resolutions.

The need to eliminate vibration

The need to

provide adequate vibration isolation presents an increasingly important and

complicated challenge, particularly at very low frequencies.

Vibration

influencing high-resolution sub-micron instrumentation can be caused by a

multitude of factors. Within the building itself, the heating and ventilation

system, fans, pumps and elevators are just some of the mechanical devices that

create vibration. How far away sensitive instrumentation is from these

vibration sources, and where in the structure the equipment is located, will

determine how strongly the equipment will be influenced. External to the

building, the equipment can be influenced by vibration from adjacent road

traffic, nearby construction, aircraft, and even wind and other weather

conditions that can cause movement of the structure.

These internal and

external influences cause low-frequency vibration in the 0.5Hz to 50Hz range,

which is transmitted through the structure and into sensitive parts of

instrumentation, compromising resolution, image quality, and the integrity of

data.

Inadequate isolation

Many

vibration isolators, particularly at frequencies below 10Hz, deliver limited

isolation vertically and even less isolation horizontally. In fact, such

isolators create vibration isolation problems in the region of their resonant

frequency. All isolators will amplify at their resonant frequency then start

isolating above this frequency. Pneumatic isolators, for example, will amplify

vibration in a typical range of 1Hz to 4Hz. Sensitive instruments, which are

typically manufactured with internal pneumatic isolation, are, therefore, often

subject to problems with vibration.

Another option in use is active feedback

electronic-force cancellation systems, which incorporate the use of sensors,

actuators, and control algorithms to detect and mitigate vibration.

Active systems have limited dynamic range,

however. They have a tough time dealing with vibration input that is either too

large or too small. Vibrations that are too large can cause the system to go

into positive feedback. Vibrations that are too small may not even be detected.

To achieve a high level of precision in vibration-critical applications,

feedback electronic-force cancellation systems must balance a complexity of

inertial feedback in response to incoming vibrations. This can be challenging

for active systems when the inertial feedback is applied to incoming

low-frequency vibrations horizontally.

As sub-micron research continues to advance

at an accelerated rate, the need to protect sensitive instrumentation –

like electron microscopes, scanning tunneling microscopes, laser

interferometers, and optical profilers – with better vibration isolation

is critical.

Negative-stiffness – the technology

behind sub-micron advanced technology

There is a more advanced

vibration isolation technology in use when it comes to protecting sensitive

sub-micron instrumentation to low-Hertz vibrations. Introduced in the mid-1990s

by

Minus K Technology, Negative-Stiffness vibration

isolation has been widely accepted for vibration-critical

applications, largely because of its ability to effectively isolate lower

frequencies, both vertically and horizontally.

Full

article...

|

|

Previous

Newsletters

|

|

|

|