Number 6, March

2010

What's Here for You:

Vibration Isolation News is designed to keep our customers and friends up to date on the latest products and applications designed to facilitate better measurements and improved nanomanufacturing. We are an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other sensitive instruments, and we have users at more than 200 leading universities and private and government laboratories in 35 countries.

INDEX

1. An Application

Comparison: Air Tables versus Negative Stiffness Technology

2. Featured

Product: BM-10 Low Profile Isolator Used Where Vertical

Space Matters

3. Featured

Application: Motion in Review-Negative-Stiffness Vibration

Isolation at Yale University

4. Upcoming

Nanotechnology Meetings and Webinars

5. Our latest Ad

6. Your comments and suggestions

An Application

Comparison: Air Tables versus Negative Stiffness Technology

Negative-stiffness

vibration isolators provide a significant improvement over

air tables in vibration-sensitive environments

Excerpted

from MR0 Today - June/July 2008

Although

air tables have been around for the better part of a half-century,

their usefulness as an efficient method for vibration isolation

is now being seriously challenged by the more compact and

effective Negative-Stiffness vibration isolators

By

Jim McMahon

For almost forty years pneumatic vibration isolators have

been the mainstay for stabilizing industrial and academia's

most critical micro-engineering instrumentation. But, just

as technology has been steadily migrating from micro to

nano, so has the need for more precise vibration isolation

in microelectronics fabrication, industrial laser/optical

systems and biological research. These so called "passive

system" air tables are now being seriously challenged

by the newer Negative-Stiffness vibration isolators. Negative-Stiffness

isolation is rapidly gaining popularity in industrial and

laboratory environments, and to no small degree because

of its ability to effectively isolate vibration in diverse

and challenging environments.

An isolator is used to solve a problem, and how bad the

problem is determines the solution you need. Since the 1960's

air tables have been used for isolation. Basically cans

of air, they are still the most popular isolators used.

But, air tables with resonant frequencies at 2 to 2-1/2

Hz can typically only handle vibrations down to about 8

to 10 Hz, not quite low enough for optimum performance with

modern nano-equipment. Also, greater isolation efficiencies

are needed in the frequency ranges air isolators can handle.

For purposes of clarity in scanning probe microscopes and

interferometers, air tables are an inefficient isolation

solution. The air systems have been adequate up until a

few years ago when better isolation was required.

Because of its very high isolation efficiencies, Negative-Stiffness

vibration isolation systems enable vibration-sensitive instruments

such as scanning probe microscopes, micro-hardness testers,

profilers and scanning electron microscopes to operate in

harsh conditions and severe vibration environments that

would not be practical with top-performance air tables and

other pneumatic isolation systems.

Negative-Stiffness versus Air Isolation

Following are ten key points which demonstrate the benefits

of Negative-Stiffness isolators compared to air isolation

systems:

#1: Low Hertz Perturbations

An air table will amplify vibrations in a typical range

of 2 to 7Hz, this is because of the natural frequencies

where air tables resonate. All isolators will amplify at

their resonant frequency, and then they will start isolating.

So, with an air table, any vibration in that range could

not only fail to be mitigated, it could be amplified. The

low cycle perturbations would just come straight through

to the instrument.

Negative-Stiffness isolators resonate at 0.5Hz. At this

frequency there is almost no energy present. It would be

very unusual to find a significant vibration at 0.5Hz.

#2: Image Clarity

Negative-Stiffness vibration isolation can reduce vibration

noise levels in Atomic Force Microscopes, for example, by

a factor of 2 to 3 when compared with top-performance air

tables. This is particularly significant for noise levels

in the sub-Angstrom range. This results in clearer images

and features not discernable with pneumatic isolation systems.

#3: Severe Vibration Environments

As nano-equipment use becomes more prevalent, lab sites

are being set up in much more severe vibration-prone environments,

such as upper floors of buildings and clean rooms. Such

severe vibration locations are too extreme for pneumatic

isolators to effectively do their job.

But Negative-Stiffness isolators perform well in such environments,

producing much better images and data than can be obtained

with even the best high-performance air tables.

#4: Harsh Environments - Vacuums,

High/Low Temperature Extremes, Radiation

Air tables are not particularly compatible when it comes

to operating in vacuums, extreme high and low temperatures,

and radiation. Yet these harsh operating environments are

often necessary when conducting research and testing, such

as with cryogenic chambers in semiconductor research.

All metal Negative-Stiffness systems can be configured which

are compatible with high vacuums and other adverse environments,

such as extreme high and low temperatures, and radiation.

With vacuums, for example, Negative-Stiffness isolators

can be used right inside the vacuum chambers. This offers

other advantages such as much lower payload weights, more

compact systems, and eliminates problems associated with

vacuum chamber feed-through.

#5: Compressed Air

Air tables require a constant supply of compressed air.

This requires either a dedicated compressed air line to

be plumbed in to your lab, a tank of pressurized gas or

a small compressor.

Even if you are lucky enough to have a dedicated compressed

air line your table's location is still limited by the length

of air line you have. Large tanks of compressed gas have

to be mounted very securely to minimize their danger. Changing

the tanks can be quite difficult and inconvenient as well.

Compressors are sources of both mechanical and acoustic

noise and are very poor choices from a vibration standpoint.

If you can get your nano-environment mechanically isolated

without having to deal with compressed air to run your vibration

isolator, then you will be better off. The nice thing about

Negative-Stiffness isolators is they do not require compressed

air. They operate purely in a mechanical mode. One less

thing you have to worry about when you are setting up your

lab and working in it.

#6: Location Selection for Vibration-Sensitive

Equipment

Let's face it, air tables are big, bulky structures, they

take up a lot of lab space. The high-performance air tables

are even bigger. This can become a limiting factor when

laying out the equipment in your lab.

Negative-Stiffness isolators are available in high-performance

bench top configurations, considerably more compact than

air tables and easy to move around. They are also available

as workstations, tables and floor platforms where these

configurations are required.

#7: Load Adjustment

Low-frequency passive vibration isolators are somewhat sensitive

to small changes in weight loads, as well as to large displacements.

Pneumatic systems utilize leveling valves to mitigate the

problem.

Negative-Stiffness isolators provide a very simple manual

adjustment to accommodate variations in weight loads. For

applications where manual load adjustment is not practical

they provide an auto-adjust system that maintains the isolator

in a precise vertical equilibrium position.

#8: Scanning Probe Microscopes

Scanning Probe Microscopes (SPMs) have vibration isolation

requirements that are unparalleled in the metrology world.

The vertical axis is the most sensitive for most SPMs. They

can also be quite sensitive to vibrations in the horizontal

axes. In order to achieve the lowest possible noise floor,

on the order of an Angstrom, isolation is always used.

Bench top air systems provide limited isolation vertically

and very little isolation horizontally. Negative-Stiffness

isolators provide increased isolation performance for SPMs

over air tables, while offering better ease-of-use and no

facility requirements.

Negative-Stiffness isolators have the flexibility of custom

tailoring resonant frequencies vertically and horizontally.

#9: Laser/Optical Equipment

Laser and optical systems, whether used in an academic lab

or in an industrial environment, are very susceptible to

vibrations from the environment. These instruments almost

always need vibration isolation. Traditionally, large air

tables have been the isolators preferred for optical systems,

but Negative-Stiffness isolators are becoming a popular

choice. Negative-Stiffness isolators provide 10 to100 times

the performance of air tables, depending on the vibration

frequency.

Laser based interferometers are extremely sensitive devices

that are capable of resolving nanometer scale motions and

features. They often have very long mechanical paths which

makes them even more sensitive to vibrations. The sophisticated

modern ellipsometry techniques that allow this high performance

rely on low noise to be able to detect fringe movement.

Properly isolating an interferometer will allow it to provide

the highest possible resolution.

Optical profilers have similar sensitivity to vibrations.

Optical component systems are often quite complex. The long

optical paths can lead to angular magnification of vibrations.

Optical air tables can make the problems worse since they

have a resonant frequency that often matches that of floor

vibrations. Negative-Stiffness 0.5Hz isolators provide isolation

in these environments when air tables simply cannot.

#10: Maintenance and Expense

Because Negative-Stiffness isolators utilize simple elastic

structures and viscoelastic materials that deform, their

isolation performance does not degrade with micromotions

typical of laboratory floors and fabrication rooms, as do

conventional pneumatic isolators.

Cost-wise, Negative-Stiffness isolators are comparably priced

to air isolators or lower priced for many applications.

The Need for a Better Vibration Isolation Solution

The need for vibration isolation will continue to increase

in importance as the precision of research and test applications

embraces smaller and smaller magnitudes of scale.

As industrial researchers and universities continue to broaden

their nano-tech work, necessitating more sensitive equipment

and expanded lab facilities, vibration-handicapped environments

will become more prevalent, and a better vibration isolation

solution will be required than what has been available for

the past almost half-century with air tables. It appears

Negative-Stiffness vibration isolation will fill that void.

The full

article can be found at: https://minusk.com/content/in-the-news/mro_today_june-july_2008.html

Featured Product: BM-10 Low Profile Isolator Used Where Vertical Space Matters

The

BM-10 bench top platform offers 10-100 times better performance

than a full size air table in a package only 4.6 inches

tall and 12 inches wide and deep. It also does this without

any air or electricity!

This vibration isolation platform is extremely easy to

use and offers extreme performance. It offers a 1.5Hz

horizontal natural frequency and our signature 0.5 Hz

vertical natural frequency. There are only two adjustments.

The BM-10 is perfect for new generations of small SPM's

that require the highest performance in a very compact

system.

This is the thinnest, smallest footprint, most portable,

and most user-friendly isolator ever offered that is capable

of delivering this level of performance.

The curve below shows the vertical ½ Hz performance

of the BM-10. It offers 10-100 times better performance

than an air table in a package many times smaller.

Minus K's BM-10 Bench Top Vibration Isolator

Typical

transmissibility curve with 1/2 Hz natural Frequency

The horizontal isolation performance of the BM-10 is the same as that of the BM-6.

Applications have included the full spectrum from Scanning Probe Microscopes (AFM, STM, NSOM, etc) and Laser/Optical systems through neurosciences, electronics, and even audio reproduction.Because Minus K products can be used under vacuum conditions and require no power for their operation, they have been used in applications ranging from ground tests of spacecraft to sensitive experiments where there can be no stray electromagnetic fields.

https://minusk.com/content/products/standard/bm-10.html

Featured

Application

Negative-Stiffness Vibration Isolation at Yale University

Excerpted from Today's Medical

Developments - March 2009

Motion in Review

By

Dr. David L. Platus, President and Founder, Minus K Technology,

Inc.

LED BY PROFESSOR LAWRENCE E. COHEN PH.D.OF YALE UNIVERSITY'S

DEPARTMENT OF CELLULAR AND MOLECULAR PHYSIOLOGY, the

small lab in room BE58 at the Yale School of Medicine has

been conducting research on neuronal activity in brain cells

to develop methods for imaging brain activity, and then

uses these methods to study the brain. The university has

been developing the method for imaging brain activity for

42 years, but it was not until several years ago that the

lab opted to move to a higher level of vibration isolation

technology to support its microscopy-imaging.

It is not unusual for universities, and industry for that

matter, to have to deal with vibrations that compromise

the imaging quality and data sets that they acquire through

microscopy. Although it is certainly the desire of every

lab to rid the unwanted vibration, conventional systems

such as air tables, have not been successful in providing

an adequate level of vibration isolation for ultra-sensitive

equipment measuring at the Angstrom and micron levels.

Such was the case with Cohen's lab at Yale, where air tables

had been the mainstay for the lab's vibration isolation

for many, many years. But now, for adequate isolation to

conduct its neuronal research at the micron level, the air

tables were not able to provide the vibration isolation

needed for the lab's research.

"Monitoring many neurons or regions simultaneously

can improve our understanding about how nervous systems

are organized," Cohen continues. "For example,

the cells in your spinal cord have to get information from

your toe, and also send information to your toe. That signal

is a propagated electrical wave of membrane potential, and

dyeing that membrane can provide an optical signal that

is used to measure that propagated wave."

The lab uses a high-speed camera to view these changes.

It has a speed of 2,000 frames-per-second with very high

quantum efficiency, which is the quantity of photons that

get converted into electrons. The camera has a quantum efficiency

of about 0.9, which converts almost all the photons into

electrons.

In

the lab's optical monitoring of brain activity,

each pixel in the recording receives light from

a small portion of neurons which have been stained

by microinjection of the dye into the brain. After

waiting for the dye to spread into the processes,

the dye can be used to monitor changes in membrane

potential in dendrites and axons.

In

the lab's optical monitoring of brain activity,

each pixel in the recording receives light from

a small portion of neurons which have been stained

by microinjection of the dye into the brain. After

waiting for the dye to spread into the processes,

the dye can be used to monitor changes in membrane

potential in dendrites and axons.

When a low magnification objective is used to form

an image of a vertebrate preparation on the lab's

464 element photodiode array, or 80 x 80 pixel CCD

camera, each pixel receives light from hundreds

or thousands of neurons.

It is also using a variety of microscopes to conduct

this research including a laser scanning 2-photon

microscope and an optical microscope. At this time,

only the optical microscope is set on the Negative-Stiffness

vibration isolation system, built by Minus K Technology.

"Measuring

in the dimension of microns still requires vibration isolation

because it is so small,'' Cohen says. ''Any small movement

in the lab environment makes a big effect. If you are viewing

at 10 , and it vibrates by 10 , then you are in big trouble.

"We were using air tables before, but the Negative-Stiffness

isolator is much better," Cohen continues. "It

reduces the vibration by a larger faction because it reduces

the vibration in the X/Y plane just as well as in the Z

plane, where the air table does not do well at all on the

X/Y plane.

Putting up with lab vibration noise problems for any amount

of time, let alone for a period of years, can only be costly

in terms of lost production, and will certainly inhibit

the progress of the research.

The

full article can be found at:

https://minusk.com/content/in-the-news/today's_medical_developments_march_2009.html

Upcoming Meetings and Webinars:

| Meeting: | Sponsor: | Dates: | Location: |

| Bozen Symposium on "Functional Nanoscience" | Beilstein Institute | May.

17, 2010 - May. 21, 2010 |

Bolzano, Italy |

| Short

Abstract: The

Beilstein Bozen symposia address contemporary issues in the

chemical and related sciences by employing an interdisciplinary

approach. Topics: Self-organization/Molecular self-assembly, Molecular motors and transport, Self-replicating biomimetic systems, Molecular magnets, Quantum effects, Imaging, Manipulation of molecules at the atomic scale/Single molecule reactions http://www.ausnano.net/iconn2010/ |

|||

| Nanotech China | Cosponsors Include: Agilent, Veeco, JEOL | May.

27, 2010 - May. 29, 2010 |

Shanghai, China |

| NSTI Nanotech 2010 | Nano

Science and Technology Institute Visit the Minus K Booth #636 at this exhibit |

Jun.

22, 2010 - Jun. 23, 2010 |

Anaheim, CA |

Short

Abstract: Nanotech

2010 rings together over 5,000 technology and business leaders

and experts from academia, government, startups and Fortune

1,000 companies. |

|||

| SPIE Optics & Photonics | Visit Minus K Booth #523 at this exhibit | Aug.

3, 2010 - Aug. 5, 2010 |

San Diego, CA |

| http://spie.org/optics-photonics.xml | |||

Comments/Suggestions: Applications in New Fields or Features of Interest to You in Our Next Newsletter:

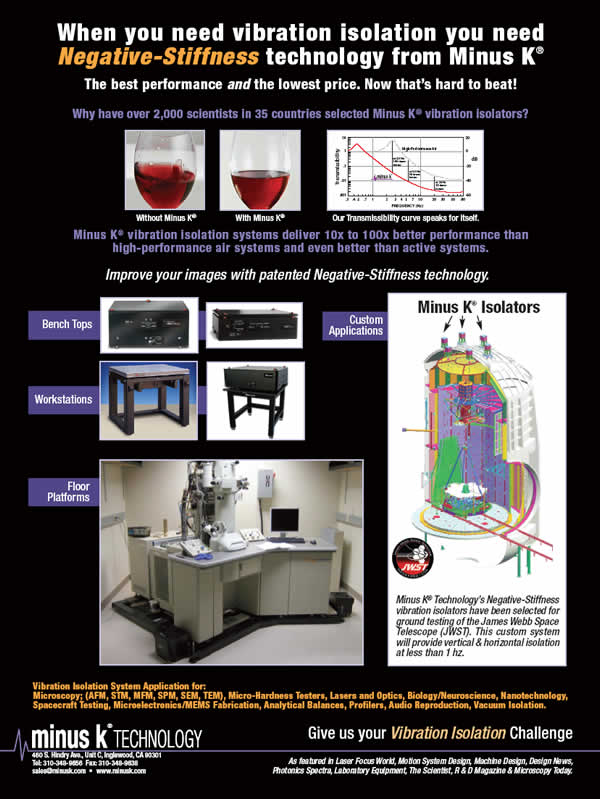

This ad will be featured in Photonics Online and The Acoustical

Society of America (JASA)

If you want

to share your application with our readers, please send us a description

so that we can publish it in an upcoming newsletter. If you have

comments or suggestions we would be very interested to read them.

Please send any materials to: david.resnik@minusk.com

Tel: 310-348-9656 Fax: 310-348-9638

Contact Us www.MinusK.com

© Minus K Technology Inc., Vibration Isolation Systems. All rights reserved.