Microscopy Today - January 2025

Microscopy Education

Enhancing the Performance of Benchtop Transmission Electron Microscopes in Noisy Environments

By Jim McMahon

Zebra Communications

Abstract: The world’s only benchtop transmission electron microscope (TEM), from Delong Instruments, combines high-contrast imaging with nanoscale resolving power. The low-voltage electron microscope can operate in four imaging modes: TEM; scanning EM (SEM); scanning transmission EM (STEM); and electron diffraction; without having to realign the column or adjust the sample, allowing both surface and transmission images of a sample to be captured from the same area of interest. Negative-stiffness vibration isolation enhances the performance of the instrument in vibration-challenged noisy environments.

Keywords:transmission electron microscopy, scanning electron microscopy, scanning transmission electron microscopy, electron diffraction, vibration isolation

Introduction

Transmission electron microscopy (TEM) utilizes a technique in which a beam of electrons is transmitted through an ultra-thin specimen, interacting with the specimen as it passes through. An image is formed from the interaction of the electrons transmitted through the specimen. The image is magnified and focused onto an imaging device, such as a fluorescent screen, a layer of photographic film, or a sensor such as a CCD camera. TEMs are capable of imaging at a significantly higher magnification than light microscopes. This enables the investigators to examine fine details, even as small as a single column of atoms. As the wavelength of an electron can be up to 100,000 times smaller than that of visible light, electron microscopes have a much higher resolution of approximately 0.1 nm.

TEM is a powerful tool for directly looking at small physical specimens. The microscope has evolved into a sophisticated instrument capable of providing structural and chemical information from solid materials over a wide range of magnification, to a level of spatial resolution that is unapproachable by most other techniques. The TEM offers a wide variety of imaging, diffraction, and microanalytical modes that can be used individually or in combination to extract essential information. As long as the instrument is aligned and used properly, many TEM techniques are available to researchers to reveal a wealth of information about their samples.

A recent development is the benchtop TEM, which enables a heightened level of location flexibility and user- friendly applications for researchers engaged in high-resolution microscopy.

Nanoscale from Your Benchtop

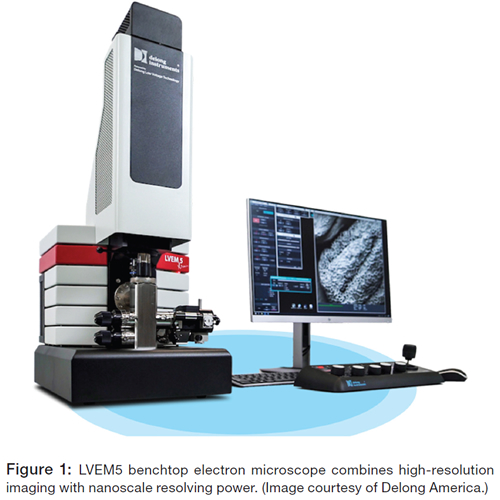

Nanoscale from Your BenchtopThe world’s only benchtop TEM design, the LVEM5 electron microscope combines high-resolution imaging with nanoscale resolving power (Figure 1). Designed and manufactured by Delong Instruments (Delong), the low-voltage electron microscope has the ability to operate in four imaging modes: TEM; scanning electron microscopy (SEM); scanning transmission electron microscopy (STEM); and electron diffraction (ED); and it provides data wit out having to realign the column or adjust the sample when changing operating modes. This allows both surface and transmission images of the sample to be captured from the same area of interest.

The LVEM5 is designed to produce detailed and meaningful image results with unmatched contrast of biologic and soft mate- rial samples and is a benefit to any lab working with, researching, or producing nano materials. The LVEM5 is approximately 90 percent smaller than classical EMs and is small enough to fit anywhere nanoscale imaging is needed. It is easy to learn, operate, and maintain, at a fraction of the cost of a conventional TEM.

LVEM5 Design and Features

5 kV Field emission gun (FEG). The electron source determines, in large measure, the parameters of the EM. The uniquely designed Schottky-type 5 kV field emission gun employed by the LVEM5 has very high brightness and spatial coherency allowing for strong interactions between the emitted electrons and the samples. This provides the LVEM5 with uniquely high contrast.

Permanent magnet lenses. The LVEM5 TEM uses permanent magnet lenses. This unique feature allows for the miniature architecture of the microscope and eliminates any cooling requirements. Conventional EMs require active cooling to remove considerable heat generated by electric current circulating in the electromagnetic lenses.

Motorized sample manipulator. The LVEM5 employs a motorized stage with joystick control of the X, Y, and Z axes for intuitive sample movement. Joystick sensitivity is dynamic, providing quick motion for low-magnification sample screening and fine precision for high-magnification imaging.

Ion getter pumps. Ion pumps are inherently dry, vibration- free, and achieve very high vacuum levels. They use no oil, as do mechanical rotary pumps and diffusion pumps. By making use of specially designed ion getter pumps, the LVEM5 avoids all contamination in the sample space, resulting in stable imaging conditions and absence of artifacts.

Airlock: turbomolecular pump with diaphragm pump. A maintenance-free turbomolecular pump provides rapid evacuation of the airlock system allowing a quick and clean sample exchange. A self-venting system allows for rapid cycle times.

Imaging controls. User operations are facilitated via an ergonomic control panel with simple adjustments for illumination, magnification, image optimization, and stage position.

Intuitive software. The included PC and monitor are delivered complete with pre-installed intuitive software for micro- scope operations and imaging. The software allows monitoring and adjustments of all important microscope parameters and makes it possible to switch seamlessly between all imaging modes. Image acquisition in all modes is carried out directly within the software, providing the capability for on-screen measurements, statistics, and fast Fourier transform (FFT) analysis. Image corrections such as image brightness and contrast, live-histogram auto-correction, and bit-depth selection are also possible. Images are saved in non-proprietary formats that can be exported for use by most image analysis software.

Installation simplicity. As a result of its small footprint and novel column architecture, the LVEM5 does not require a dedicated room, anti-vibration isolation, special power supply, or cool- ing of any kind, thereby simplifying the instrument’s installation.

Versatile Functionality

TEM. Electron optics provide the initial stages of magnification. The FEG cathode is at the base of the microscope. The electron beam is then shaped by the condenser and objective lenses as electrons travel upward through the sample. They continue toward the yttrium aluminum garnet (YAG) scintillator screen for formation of the initial image. High spatial resolution on the YAG screen enables the use of high light-optical magnification in a unique two-stage magnification system.

Light optics that are stable and reliable further magnify the initial image on the YAG screen. There is highly efficient light transport from the luminescent screen into the light optics. A selection of different light objectives allows for two ranges of magnification. Image capture is by means of a scientific CMOS (complementary metal–oxide–semiconductor) digital camera mounted on the top of the LVEM5. The camera is optimized for low-light, high dynamic range image capture. The magnified image from the light optics is captured for subsequent viewing and analysis.

SEM. A backscattered electron detector has been incorporated directly into the electron optics, enabling SEM. Backscattered electrons (BSEs) are collected by an annular solid-state detector separately for each scanned point, offering a stereoscopic view of the sample. The spatial intensity distribution of the BSEs is used to form the final image in the software.

The combination of selected spot sizes and optimized working distances allow for a wide range of magnifications. The small working distance creates high spatial resolution, and a segmented detector provides the choices of material or relief contrast.

With the click of a button, the SEM mode is accessed easily to view the same area of interest for topographical information.

STEM. A STEM imaging option can be added to the base configuration of the LVEM5. Unlike SEMs with STEM add-ons, the LVEM microscope offers high-quality and well-contrasted images. With the addition of a STEM photomultiplier, samples that are too dense for TEM imaging mode can be imaged. The low voltage inherent with the LVEM5 microscope ensures strong interaction with samples allowing for higher contrast imaging.

ED. Diffraction mode in LVEM5 is easily accessible from the TEM mode, and acquired patterns can be attributed to specific areas or features (grains, particles, phases) present in the sample. Subsequent analysis of acquired diffraction patterns can provide information on crystal structure, degree of crystallinity, and phase composition of the sample. Polycrystalline areas generate ring diffraction patterns, while single crystals or highly textured thin films produce dot patterns. For diffraction imaging, the sample must be electron-transparent at the operating voltage of the microscope, free of contamination and damage, and surface topography must be maintained to a minimum.

Sensitivity to Vibration in Noisy Environments

TEM, like other high-resolution microscopy, is influenced by factors such as magnetic fields, barometric pressure changes, room temperature variations, grounding problems, and floor vibrations. Floor vibrations can originate from movement of outside vehicle traffic, elevators, HVAC systems, building pumps and motors, and ancillary equipment providing support for the microscope. Both vertical and horizontal vibration can negatively influence the focus and resolution of the images being viewed.

The benchtop LVEM5 is designed to be well-isolated from outside fields and vibrations, providing an adequate level of stability for the instruments installed in the average lab environments. However, these high-resolution instruments are most sensitive to low-frequency vibration, in the range of a few Hertz (Hz), which are prevalent in noisy environments. These low-Hz vibrations are challenging to eliminate from the microscope’s environment.

Eliminating Vibration from Reaching the Benchtop TEM

Introduced in the mid-1990s by Minus K Technology (Minus K), negative-stiffness vibration isolation has been widely accepted for vibration-critical applications, largely because of its ability to effectively isolate lower frequencies, both vertically and horizontally. These isolators are used in a broad spectrum of applications including microscopy, nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft, and high-end audio, making them an ideal fit for

Delong’s benchtop LVEM5 TEM.

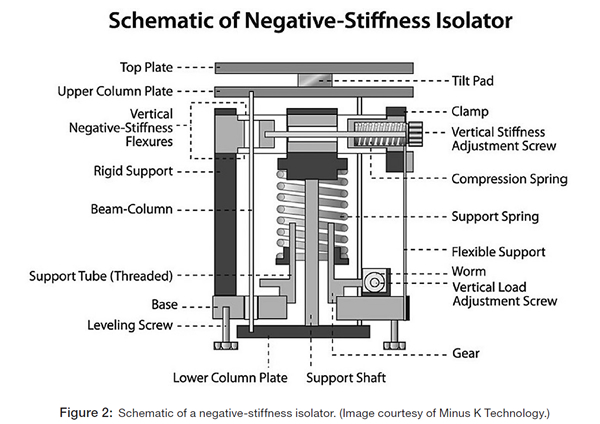

Negative-stiffness isolators are unique in that they operate purely in a passive mechanical mode. They do not require electricity or compressed air. There are no motors, pumps, or chambers, and no maintenance because there is nothing to wear out. Vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a negative-stiffness mechanism.

The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation. A beam-column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and high internal structural frequencies (Figure 2).

Negative-stiffness isolators achieve a high level of isolation in multiple directions, with the flexibility of custom-tailoring resonant frequencies to 0.5 Hz vertically and horizontally (with some versions at 1.5 Hz horizontally). When adjusted to 0.5 Hz, the isolators achieve approximately 93% isolation efficiency at 2 Hz, 99% at 5 Hz, and 99.7% at 10 Hz. For an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with an increase in vibration frequency. The natural frequency is more commonly used to describe the system performance.

Conclusion

In combination, the LVEM5 and negative-stiffness vibration isolation systems provide a versatile system for electron microscopy imaging in many environments for several types of samples. The small footprint of the system provides an ideal instrument for limited space environments.

|