MonoandStereo.com - August 2020

IMPROVING SOUND QUALITY WITH THE LATEST TECHNOLOGY IN VIBRATION ISOLATION

Jim McMahon writes: “Using a totally passive mechanical system, without the need for electricity or compressed air, the latest vibration isolation technology for extremely sensitive audio reproduction systems provides an unprecedented 0.5 hertz isolation performance vertical, and 1.5 hertz horizontal, delivering a significant advance in sound quality. With recorded discs, sound waveforms are captured in the disc grooves with microscopic undulations. The turntable’s cartridge and stylus trace these minute wave forms, play them back with very sensitive low voltages and convert them into an audio signal. This is how the sound captured in the record grooves is reproduced. But this process is extremely sensitive to movement.

Vibration isolation in the playback process of high-end audio systems is crucial. Any external vibration, no matter how slight, even someone walking near the turntable or vibration from floor-mounted speakers, is sensed by the turntable’s stylus and affects the sound being played back from the record. Capacitors, resistors, transistors, tube amplifiers and other electronic components are can be sensitive to vibration.

External to the building, audio equipment can be influenced by vibrations from adjacent road traffic, nearby construction, loud noise from aircraft, and even wind and other weather conditions that can cause movement of the structure. Noise from people walking on the floor, footfall, can be especially problematic in residential houses, where floors are typically not as stiff as within laboratories and manufacturing facilities.

Vibrations in the range of 20 hertz (Hz) to 20,000 Hz will influence the sound reproduction in audio systems. But these internal and external influences primarily cause lower frequency vibrations which are transmitted through the structure, creating strong disturbances in sensitive, high-end audio systems. However, frequencies as low as 2 Hz can also have adverse effects as well.

Vibration within this range can be caused by a multitude of factors. Every structure is transmitting noise. Within the home or building itself, the heating and ventilation system, fans, pumps and elevators are just some of the mechanical devices that create vibration.

Depending on how far away the audio system is from these vibration sources, and where in the structure the audio system is located, whether on the third floor or in the basement, for example, will determine how strongly the sound quality will be influenced and by what frequencies.

CONVENTIONAL VIBRATION ISOLATION

Most manufacturers of high-end turntables recognize that external vibration is a problem, and will go to great lengths to minimize it in their turntable designs. Quality turntables, for example, are built with superb platter bearings to minimize rumble. They often incorporate high-mass platters that are designed to increase speed stability and reduce flutter. They might use exotic materials to dampen vibrations without deadening the sound. Tone arms have their own set of vibration and resonance characteristics which manufacturers attempt to isolate from the audible frequencies through geometry, localized vibration isolation and damping. Turntable designers go through this elaborate process to try and eliminate vibration throughout the entire turntable playback structure.

High-end turntables are sometimes factory-equipped with built-in vibration isolation supporting the entire unit. But the majority of turntables are manufactured without factory-installed vibration isolation. Here, third-party air-based vibration isolators have become a popular accessory. These systems typically have a power pump to supply air, with a tank that holds the pressurized air and delivers steady pressure to the isolator. The somewhat noisy pump is usually located outside of the room where the audio equipment is located, and the air hoses are run over to the tank and vibration isolating platform.

Air systems are usually a less than optimal set-up, however. They do achieve some isolation – usually in one dimension (vertically), and provide limited horizontal isolation. But they do not isolate to the extent that is really needed at very low resonance frequencies.

Air systems will actually amplify, instead of reduce, vibrations in a typical range of 2 Hz to 7 Hz because of the natural frequencies at which air tables resonate. All isolators will amplify at their resonant frequency, and then they will start isolating. So with air tables, any vibration in that resonant frequency range could not only fail to be attenuated, it could be amplified. In this case, the low cycle perturbations will come straight through to the audio system.

Another option is active vibration isolation systems. Also known as electronic force cancellation, active isolation uses electronics to sense the motion, and then adds forces electronically to effectively cancel out or prevent it. Some active isolation systems can start isolating as low as 0.7 Hz. But active systems have a limited dynamic range that is easy to exceed, which may cause the isolator to go into positive feedback and generate noise.

NEGATIVE-STIFFNESS VIBRATION ISOLATION

The latest vibration isolation technology gaining popularity for use with extremely sensitive audio reproduction systems is Negative-Stiffness vibration isolation. Negative-Stiffness technology was originated to eliminate vibrations in ultra-sensitive research with atomic force microscopy and nanotechnology. Today, it is widely used by government agencies like NASA and the Department of Energy, as well as in hundreds of university research facilities worldwide, where ultra-precision vibration stabilization is required.

Developed and patented by Minus K Technology (www.minusk.com), Negative-Stiffness isolators provide a unique capability to the field of audio fidelity, employing a completely mechanical concept in low-frequency vibration isolation, with no air or electricity required.

New CT-1 Low-height, low-hertz Negative Stiffness isolator. At just 2-1/4 inches in height with 0.5 Hz vertical and 2 to 2-1/4 Hz horizontal natural frequencies, the latest edition of the highest performing Negative-Stiffness vibration isolation systems for audiophiles has just gone ultra-thin and ultra-compact for optimized space configuration.

Whether with turntables, tube electronics, CD transports or other audio equipment, Negative-Stiffness isolators have the flexibility of custom tailoring resonant frequencies vertically to 0.5 Hz* and horizontally to 1.5 Hz (with some products as low as 0.5 Hz horizontally).

(*Note that for an isolation system with a 0.5 Hz natural frequency, isolation begins at 0.7 Hz and improves with increase in the vibration frequency. The natural frequency is more commonly used to describe the system performance.)

Schematic of a Negative-Stiffness isolator.

What is very advantageous about Negative-Stiffness isolators is that they achieve a high level of isolation in multiple directions. Not just vertically – which is very important for audio systems to isolate against footfall – but also in all horizontal directions. The horizontal axis is often overlooked because horizontal building vibrations are less obvious, but nevertheless, transmitted to the turntable and other audio equipment.

VIBRATION TRANSMISSIBILITY

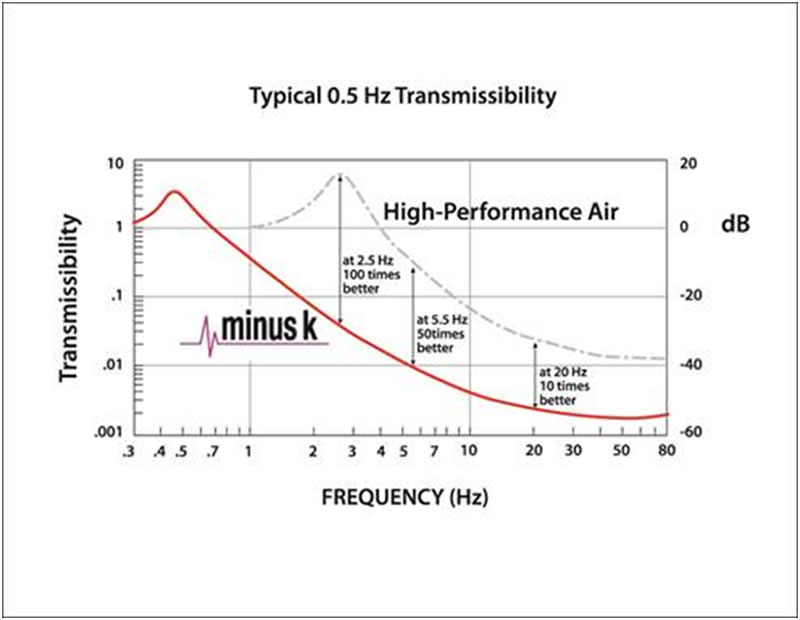

Vibration transmissibility is a measure of the vibrations that are transmitted through the isolator relative to the input vibrations. Negative-Stiffness isolators, when adjusted to 0.5 Hz, achieve approximately 93 percent isolation efficiency at 2 Hz; 99 percent at 5 Hz; and 99.7 percent at 10 Hz. Negative-Stiffness isolators deliver very high performance, as measured by a transmissibility curve.

Transmissibility with Negative-Stiffness isolation is substantially improved over air systems, which can make vibration isolation problems worse, since they have a resonant frequency that can match that of floor vibrations. Transmissibility is also improved compared to active isolation systems, which have fundamentally no resonance, but their transmissibility does not roll off as fast as Negative-Stiffness isolators.

Negative-Stiffness isolator animation

Negative-Stiffness isolators resonate at 0.5 Hz. At this frequency there is almost no energy present. It would be very unusual to find a significant vibration at 0.5 Hz. Vibrations with frequencies above 0.7 Hz (where negative-stiffness isolators begin isolating) are rapidly attenuated with increases in frequency.

Vibration transmissibility compared, Negative-Stiffness compared to air tables.

Negative-Stiffness isolators are extremely effective at cancelling out large vibrations, such as footfall. If a turntable is set up on anything other than a concrete slab floor or other large inert mass, then every time someone walks in the vicinity of the turntable, the vibrations from their footsteps are transmitted through the floor to the support stand and into the turntable, and finally show up in the sound reproduction. People will literally tiptoe around their audio playback systems, but the playback process is so sensitive that it can still pick up footsteps in the hallways or rooms some distance away.

SIMPLER IS BETTER

If audio systems can be isolated from vibrations without having to deal with compressed air or electricity, then it makes for a system that is simpler to install, easier to set-up, and more reliable to operate and maintain over the long-term.

For example, because active system isolators run on electricity they can be negatively influenced by problems of electronic dysfunction and power modulations. And air tables need a constant supply of compressed air, which requires a compressor to be located near the audio set-up. Compressors are sources of both mechanical and acoustic noise and have the potential to be part of the problem rather than the solution. Not the best choice from a vibration elimination standpoint.

Negative-Stiffness isolators do not require electricity or compressed air. There are no motors, pumps or chambers, and no maintenance because there is nothing to wear out. They operate purely in a passive mechanical mode.

These isolators provide a great deal of flexibility. For example, it is possible to configure a state-of-the-art mobile turntable that can be moved around a facility without having to worry about electrical power and pumps, or whether it is located in the basement or on the second floor.

THE SOUND

People who care about sound quality – like audiophiles, musicians and recording engineers – can have very strong, subjective preferences about what constitutes good sound. Some people like resonances in their system that emphasize particular frequencies, so they will insist, for example, that their equipment must rest on a maple wood support because it has a certain resonance that makes the sound more appealing to them. Others want to experience sound as the mastering or recording engineer intended it, without further coloration. However, serious audiophiles uniformly agree that vibration is an unwanted condition which diminishes sound quality.

According to many audiophiles, Negative-Stiffness isolators enable a sense of harmonic rightness. Instruments sound much more like real instruments, and voices sound like they are in a real acoustic space, with real air around them. The ability to “see” clearly into the entire three-dimensional soundstage is greatly enhanced. Improvements in rhythm and pace are captivating. This latest generation of vibration isolation technology truly represents a significant advance in sound quality for high-end audio.

About Minus K Technology, Inc.

Minus K® Technology, Inc. was founded in 1993 to develop, manufacture and market state-of-the-art vibration isolation products based on the company’s patented negative-stiffness technology. Minus K products are used in a broad spectrum of applications including microscopy, nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft, and high-end audio. The company is an OEM supplier to leading manufacturers of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. Minus K customers include private companies and more than 300 leading universities and government laboratories in 50 countries.

Dr. David L. Platus is the inventor of negative-stiffness isolators, and President and Founder of Minus K Technology, Inc. (www.minusk.com). He earned a B.S. and a Ph.D. in Engineering from UCLA, and a diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to founding Minus K Technology he worked in the nuclear, aerospace and defense industries conducting and directing analysis and design projects in structural-mechanical systems. He became an independent consultant in 1988. Dr. Platus holds over 20 patents related to shock and vibration isolation.

For more information on negative-stiffness isolators please contact Steve Varma, Minus K Technology, Inc.; 460 Hindry Ave., Unit C, Inglewood, CA 90301; Phone 310-348-9656; Fax 310-348-9638; email sales@minusk.com; www.minusk.com.

*****************

Jim McMahon writes on advancements in instrumentation technology. His features have appeared in hundreds of publications worldwide. jim.mcmahon@zebracom.net

|